Custom PCB manufacturing has become a key driver of innovation. From smartphones to industrial machinery and IoT devices, the Printed Circuit Board (PCB) forms the backbone of all electronics. Companies like Baiyoudi, a leading PCB manufacturer, leverage advanced PCB fabrication and PCB assembly techniques to meet the demands of modern electronics.

1️⃣ Why PCB Design Matters in Modern Electronics

A well-designed PCB ensures efficient component placement and enhances device performance. Innovations such as multilayer PCB fabrication allow for compact, high-density layouts that reduce signal interference and improve electrical performance.

💡 Benefits include:

-

Smaller, lighter devices

-

Reduced electromagnetic interference

-

Enhanced thermal management

Advanced software tools now allow precise routing, thermal planning, and electromagnetic compatibility (EMC) considerations, ensuring reliable performance from design to production.

2️⃣ Advantages of Custom PCB Manufacturing 🛠️

Custom PCB manufacturing offers flexibility that off-the-shelf boards cannot:

-

Optimized Space Utilization: Perfect for miniaturized electronics like wearables and IoT devices.

-

Improved Electrical Performance: Controlled trace width, material choice, and layer stack ensure better signal integrity.

-

Enhanced Thermal Management: Thermal vias, heat sinks, and optimized copper layers maintain stable operation.

-

Cost-Effective Production: Reduces waste and assembly errors for long-term savings.

Baiyoudi provides complete PCB fabrication and PCB assembly services, from prototyping to large-scale production.

3️⃣ Innovations in PCB Fabrication 🧩

Modern PCB fabrication includes:

-

Multilayer PCB Fabrication: Supports compact, high-speed, high-performance designs.

-

High-Density Interconnect (HDI): Microvias and fine traces for dense connections in small devices.

-

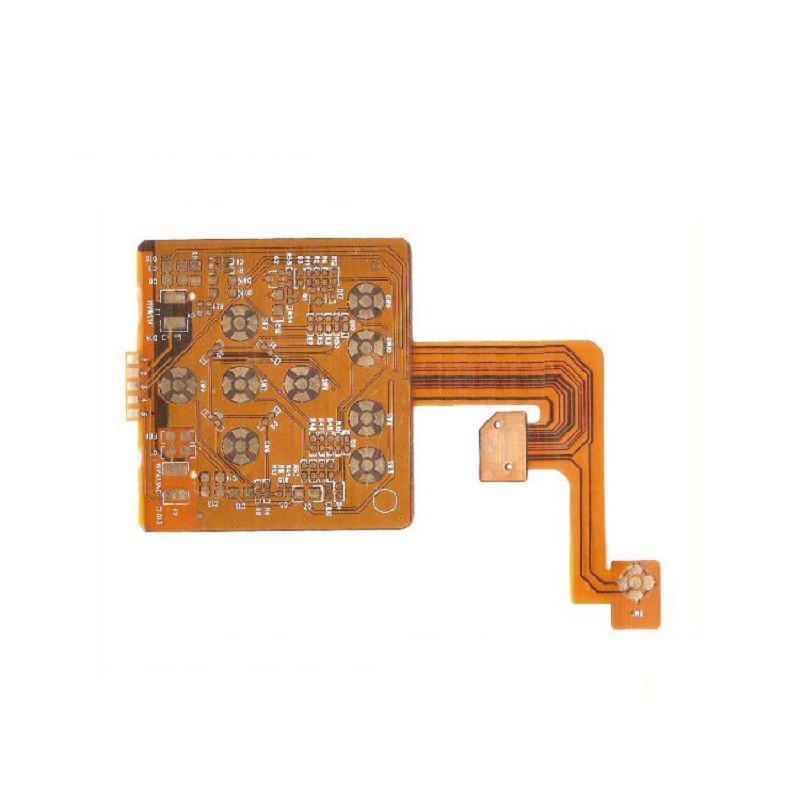

Flexible & Rigid-Flex PCBs: Enable foldable devices and wearable electronics.

-

Advanced Surface Finishes: ENIG and other finishes improve solderability and durability.

These innovations directly improve device performance, reliability, and longevity.

4️⃣ The Role of PCB Assembly ⚙️

Seamless PCB assembly complements fabrication:

-

Automated pick-and-place machines

-

Precision soldering

-

Rigorous testing procedures

This ensures high-quality boards, reduces defects, and increases reliability. Custom PCB manufacturing by Baiyoudi allows both small-batch prototypes and large-scale production, adapting to various project needs.

5️⃣ Impact Across Industries 🌎

Innovations in custom PCB manufacturing affect multiple sectors:

| Industry | Impact of Custom PCBs |

|---|---|

| Consumer Electronics | Compact, high-performance smartphones, laptops, smart home devices |

| Automotive | Reliable ADAS, EV battery systems, infotainment systems |

| Industrial | Robust robotics, sensors, machinery electronics |

| Healthcare | Precision medical devices, patient monitoring equipment |

Multilayer designs and high-quality PCB assembly allow products to be more reliable, efficient, and powerful.

6️⃣ Future Trends in PCB Manufacturing 🚀

-

AI-Assisted PCB Design: Optimizes layout, routing, and thermal management automatically.

-

Sustainable Manufacturing: Eco-friendly materials and processes reduce environmental impact.

-

Embedded Components: Integrates active/passive components into the PCB substrate.

-

IoT & 5G Ready PCBs: High-frequency, high-speed designs for next-gen connectivity.

Baiyoudi stays at the forefront, offering full custom PCB manufacturing solutions for evolving industry demands.

✅ Conclusion

Design innovations in custom PCB manufacturing are reshaping modern electronics. With advanced multilayer PCB fabrication, precise PCB assembly, and efficient PCB fabrication methods, engineers can create compact, high-functioning devices for consumer, industrial, automotive, and medical sectors.

Baiyoudi, as a professional PCB manufacturer, ensures high-quality, reliable, and innovative custom PCB manufacturing solutions that drive the electronics industry forward.