PCBA: The Beating Heart of Your Electronics – Why It Makes or Breaks Your Product

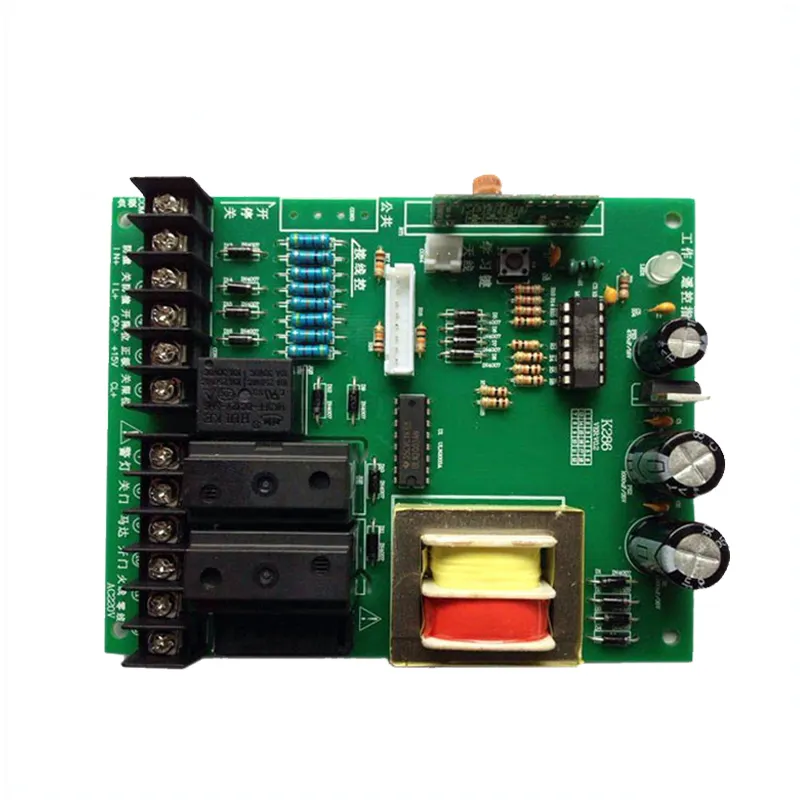

PCBA (Printed Circuit Board Assembly) is the critical stage where a bare PCB transforms into a functional electronic device. Unlike a PCB, which consists only of conductive traces on a bare board, a PCBA integrates all electronic components—such as resistors, ICs, and connectors—through precise soldering, resulting in a fully operational circuit ready for end-use applications.

A PCB (Printed Circuit Board) serves as the foundational mechanical and electrical platform, featuring conductive copper traces laminated onto an insulating substrate. However, it only becomes a PCBA (Printed Circuit Board Assembly) once all required electronic components—such as resistors, capacitors, ICs, and other passive/active devices—are mounted and soldered, transforming it into a functional electronic system.

Why Choose Our PCBA Manufacturing Services?

For 13 years, we’ve been delivering precision PCBA solutions trusted by global electronics brands. Our ISO 9001-certified facilities in Shenzhen combine cutting-edge SMT technology with proven manufacturing excellence to bring your designs to life – from rapid prototypes to high-volume production.

Key Advantages:

✅Industry-Leading Speed: 12-24 hour turnaround on express prototyping

✅ Exceptional Quality: 98.5% first-pass yield rate

✅No MOQ Restrictions: Flexible production from 1 unit to 100,000+

✅Global Compliance: Meet international standards for medical, automotive, and industrial applications