Efficient PCB manufacturing is crucial for businesses that want to deliver high-quality products on schedule. From prototypes to mass production, understanding cost and lead time factors can save time and money. Baiyoudi, a trusted OEM PCB manufacturer, shares key considerations for printed circuit board manufacturing.

PCB Design Complexity

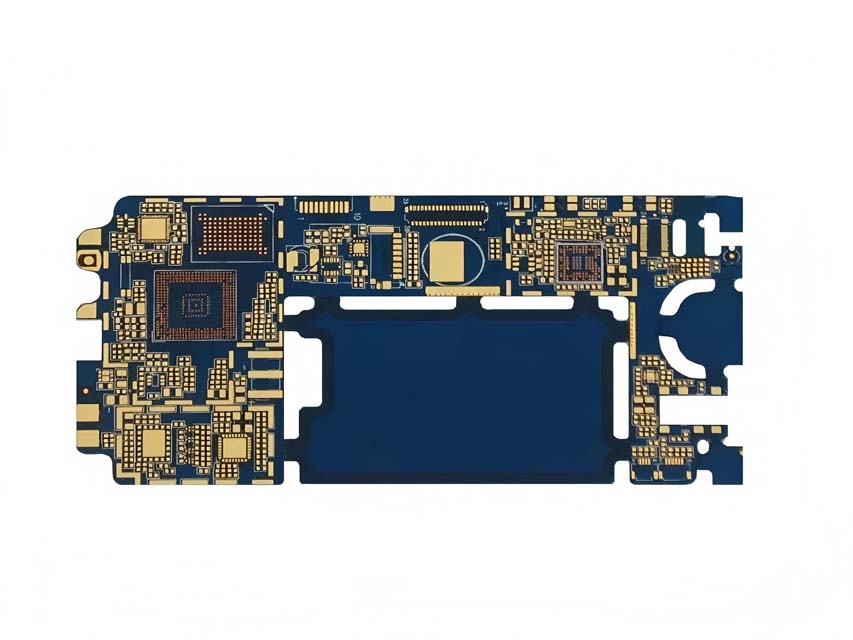

The design of a PCB greatly impacts cost and lead time. Multi-layer boards, high-density components, and fine-pitch routing require advanced PCB fabrication techniques. These designs need precise drilling, plating, and lamination. Each step adds time and cost. Baiyoudi works with clients to optimize designs. This balances manufacturability, performance, and efficiency, reducing production delays.

Material Selection

Materials also affect both price and production speed. Standard FR4 is cost-effective and common for most applications. High-frequency laminates, ceramics, or flexible substrates are more expensive. They also require extra processing.Choosing the right material ensures proper electrical and thermal performance. Baiyoudi advises clients on optimal substrates for industrial, automotive, or consumer electronics applications.

Board Size and Order Quantity

The size of the PCB and the quantity ordered directly affect costs. Large boards use more raw material and may need specialized equipment. Small batches or prototypes carry higher per-unit costs. Bulk orders reduce per-unit cost but may increase lead time. Baiyoudi offers flexible production solutions. Both low-volume prototypes and high-volume runs can be produced efficiently.

Surface Finish and Plating

Surface finishes like HASL, ENIG, and OSP impact solderability and durability. Higher-end finishes offer better performance but cost more and extend lead times.

Baiyoudi provides multiple surface finish options. Each is tailored to the precision and reliability requirements of the product.

Component Availability

Efficient PCB assembly services depend on timely component sourcing. Rare or custom parts can delay production. Coordinated procurement ensures smooth assembly. Baiyoudi manages global supply chains to minimize delays. This ensures reliable and timely delivery.

Testing and Quality Control

Testing is essential for printed circuit board manufacturing. Functional tests, in-circuit testing (ICT), and X-ray inspections ensure reliability. Applications in automotive, medical, or aerospace industries require rigorous testing. Baiyoudi integrates quality control throughout production. This reduces rework, avoids delays, and ensures high-yield boards.

Advanced Manufacturing Technology

Automation and modern equipment improve efficiency and reduce costs. SMT lines, precise drilling, and lamination equipment enhance production speed and quality.Baiyoudi continually upgrades technology. This supports high-precision PCB fabrication while maintaining competitive pricing.

Regulatory Compliance

Standards such as ISO, UL, RoHS, and IPC ensure safety and environmental compliance. Meeting these standards may require extra steps but guarantees reliable boards. Baiyoudi ensures all products meet regulatory requirements without delaying production.

Logistics and Delivery

Location and logistics influence lead time. Local manufacturing reduces shipping delays. International orders may experience longer delivery times due to customs or transportation. Baiyoudi provides global logistics solutions. Costs and delivery schedules are balanced for client convenience.

Conclusion:

Multiple factors determine the cost and lead time of PCB manufacturing. These include design complexity, material choice, board size, surface finish, component sourcing, testing, equipment, compliance, and logistics.

Partnering with a reliable OEM PCB manufacturer like Baiyoudi ensures access to expert PCB fabrication and PCB assembly services. Businesses benefit from optimized costs, timely delivery, and high-quality printed circuit board manufacturing, supporting successful product launches.