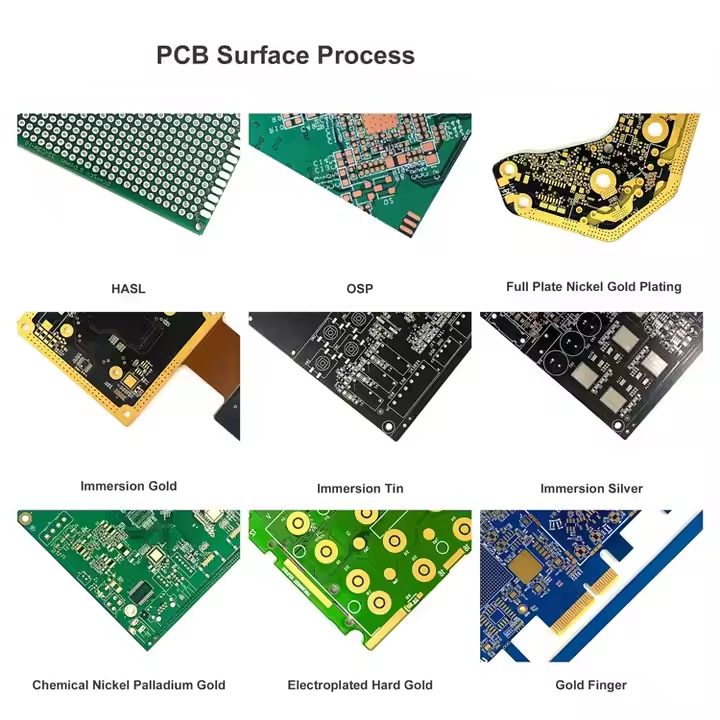

PCB Surface Finishes

Essential PCB Surface Finishes

Printed Circuit Board (PCB) surface finishes protect copper traces from oxidation and ensure reliable solder-ability during assembly. This guide covers key finishes, technical specifications, and industry applications—critical for design engineers and PCB manufacturers.

Hot Air Solder Leveling (HASL)

Process: PCBs are immersed in molten solder (lead or lead-free), then leveled with hot air knives.

Thickness: 1–40 μm 48

Pros:

Excellent solderability

Low cost

Shelf life: 12+ months

Cons:

Poor planarity (uneven surfaces)

Unsuitable for fine-pitch components (<20 mil spacing) or HDI designs 46

Applications: Consumer electronics, low-density boards.

Organic Solderability Preservative (OSP)

Process: Forms a thin organic layer (benzimidazole-based) on copper to prevent oxidation.

Thickness: 0.15–0.65 μm 48

Pros:

Flat surfaces ideal for BGA/micro-pitch components

Eco-friendly, low-cost process

Cons:

Short shelf life (6 months max)

Degrades after 2–3 reflow cycles 610

Applications: High-density ICs, smartphones, TVs.

Electroless Nickel Immersion Gold (ENIG)

Process: Deposits a nickel-phosphorus (Ni-P) barrier layer (3–6 μm), topped with immersion gold (0.05–0.125 μm) .

Critical Parameter: Phosphorus content (7–10%) prevents “Black Pad” defects.

Pros:

Superior planarity for BGA/LGA

Long shelf life, wire-bondable

Cons:

High cost

Risk of brittle solder joints if Au >0.3 μm 1

Applications: Connectors, switches, RF devices.

Immersion Silver (IAg)

Process: A sub-micron silver layer deposited via displacement reaction.

Thickness: 0.12–0.40 μm

Pros:

Excellent high-frequency signal integrity

Moderate cost

Cons:

Tarnishes easily (requires glove handling)

Limited shelf life after packaging opened 8

Applications: Automotive, high-speed PCBs, communication hardware.

Immersion Tin (ISn)

Process: Forms a copper-tin intermetallic compound (IMC) for direct soldering.

Thickness: 1–40 μm 4

Pros: Compatible with all solder types; Flat surfaces

Cons: Prone to tin whiskers (mitigated by organic additives) 16

Short storage window

Applications: Backplanes, telecom infrastructure.

Specialized Finishes

Electrolytic Ni/Au (Hard Gold):Hard Au (with cobalt): 0.5–1.5 μm for connectors/fingers 37.

Soft Au:>1 μm for wire bonding.

ENEPIG (Ni-Pd-Au): Pd layer prevents corrosion, used in aerospace 7.