Talk to our experts today and bring your next product idea to life.

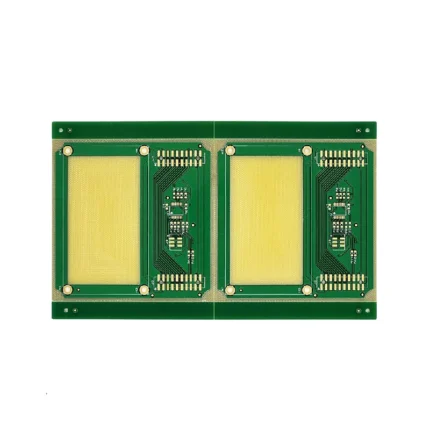

Whether you need simple single-layer Flex PCBs for cost-sensitive applications or complex multilayer rigid-flex designs for advanced electronics, our engineering team can optimize the solution for your specific requirements. The combination of our material expertise, advanced manufacturing capabilities, and rigorous quality control ensures reliable performance in even the most demanding environments. Contact us today to discuss how Flex PCB technology can enhance your product design with improved reliability, reduced weight, and greater packaging flexibility.

Unmatched Flexibility Meets High Reliability

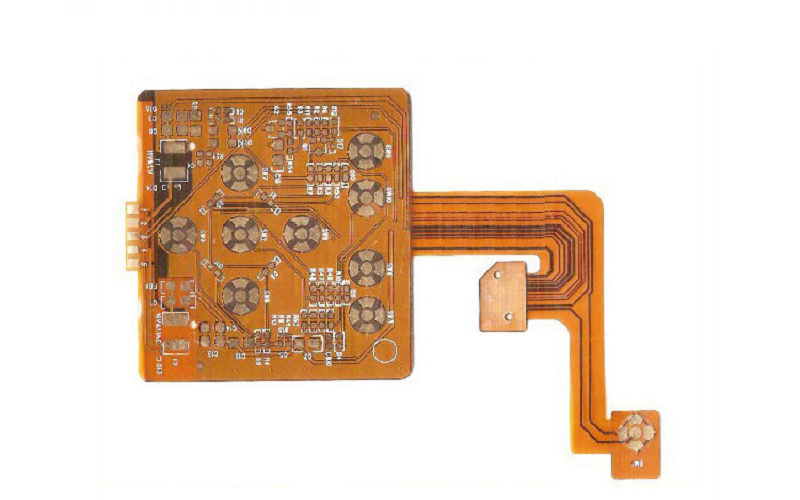

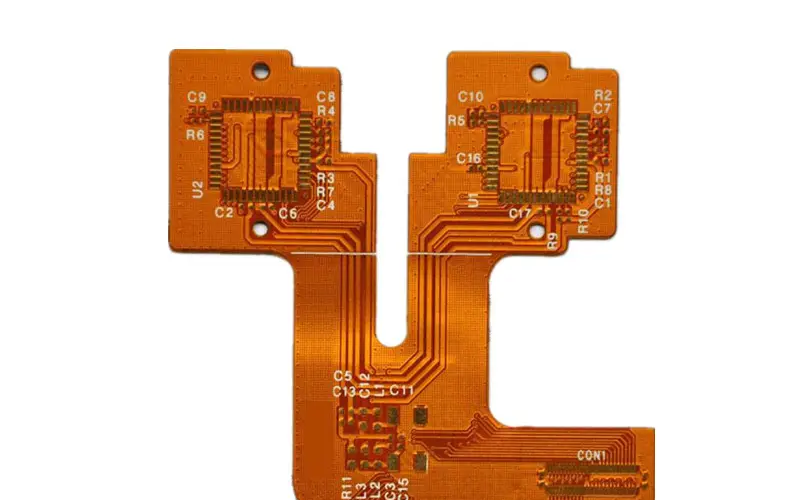

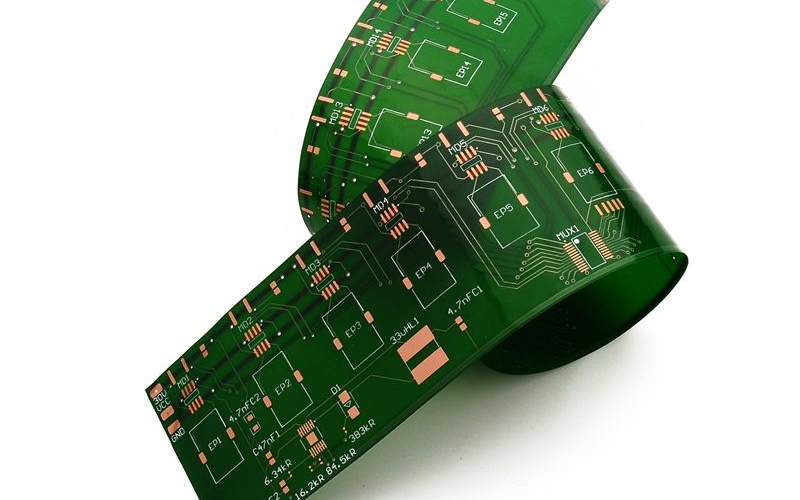

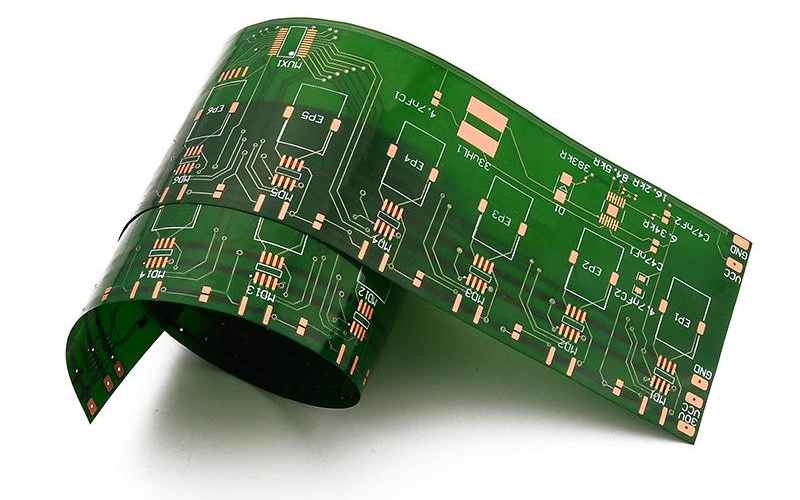

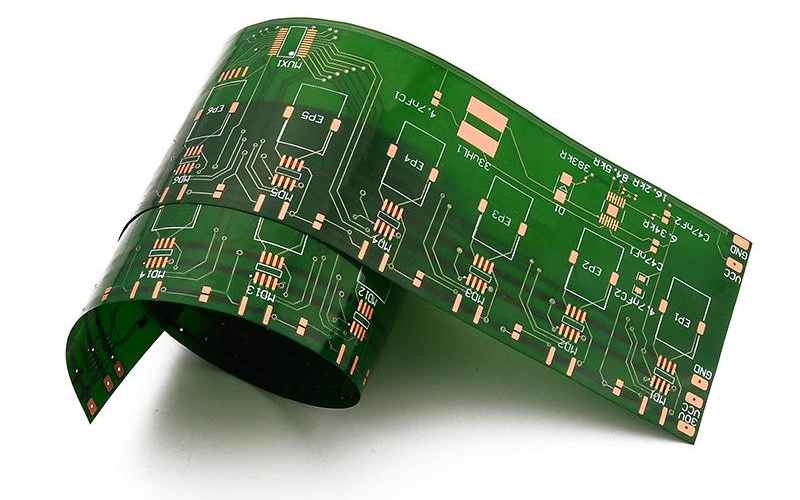

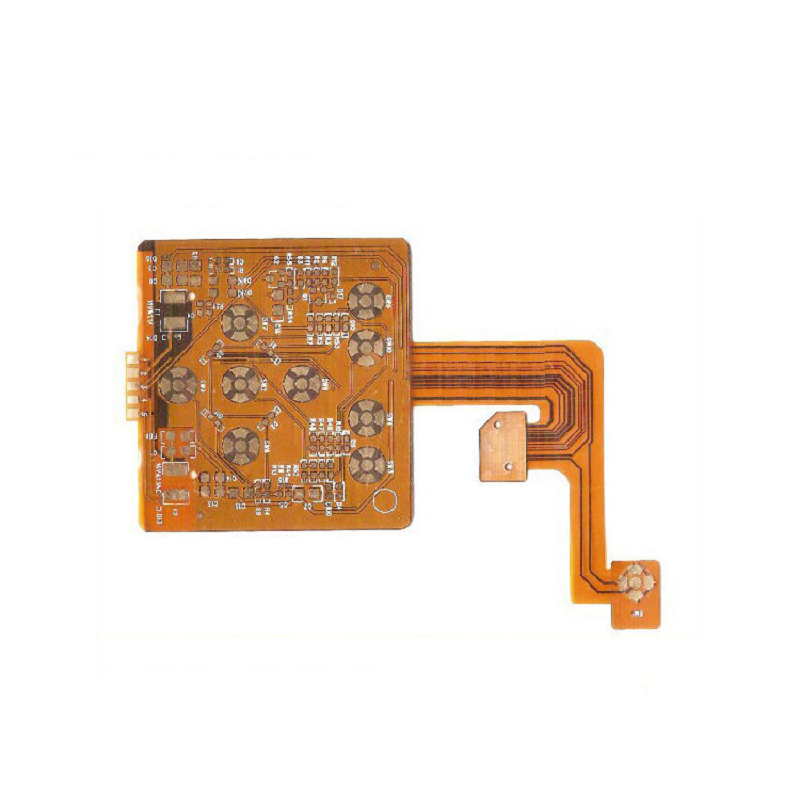

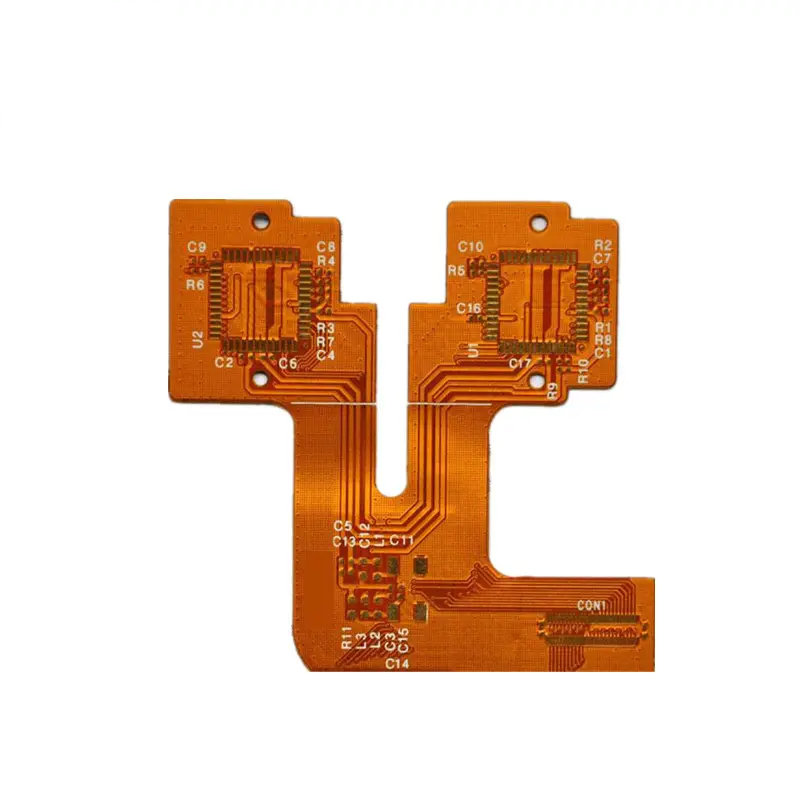

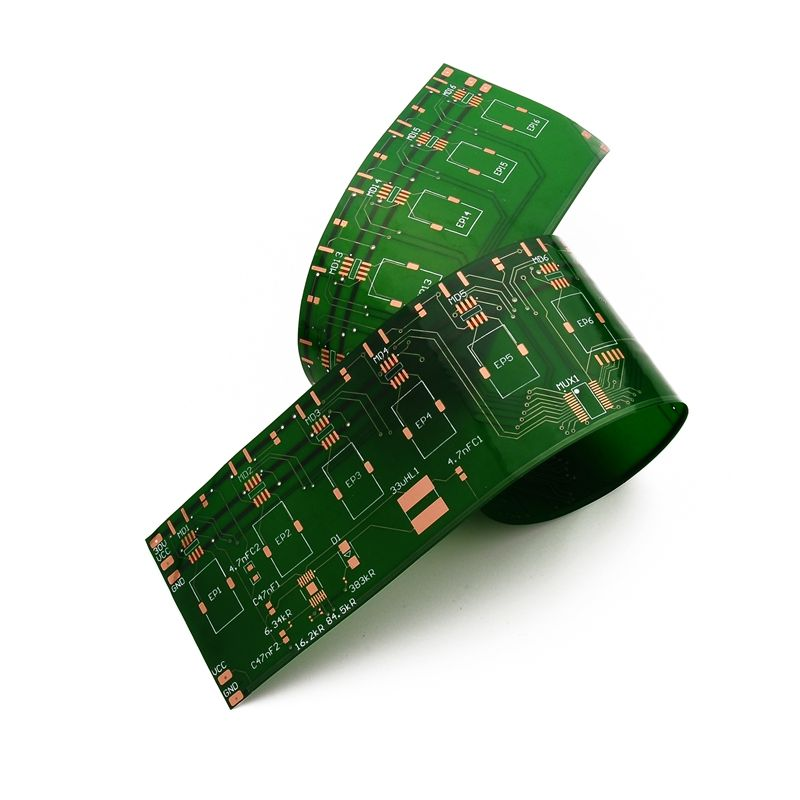

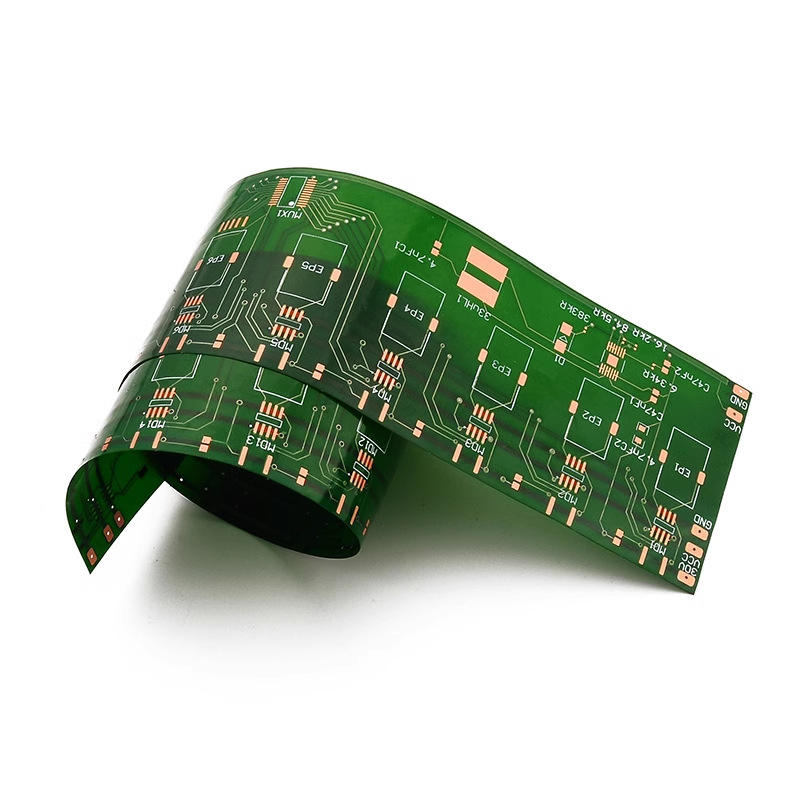

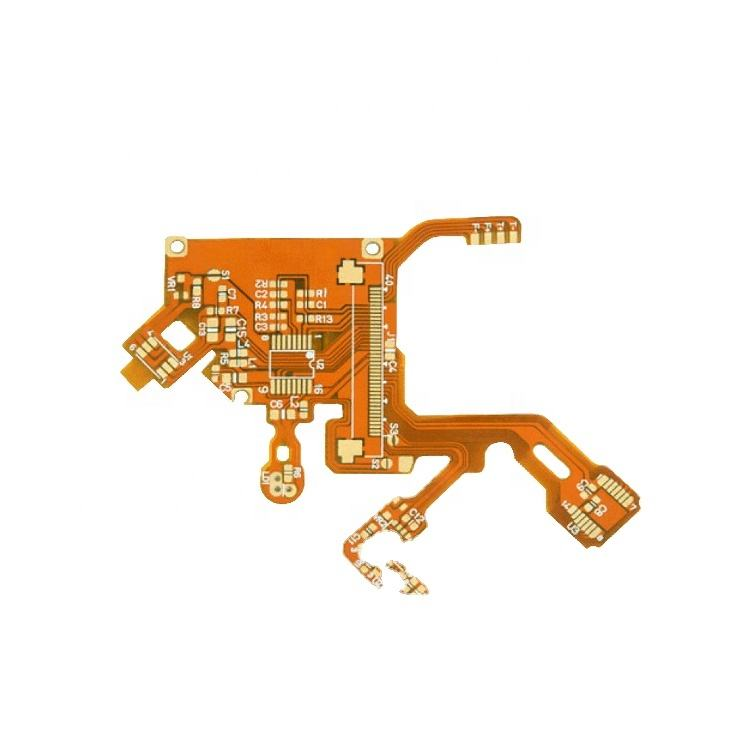

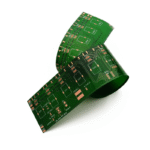

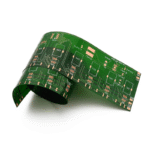

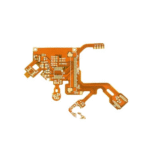

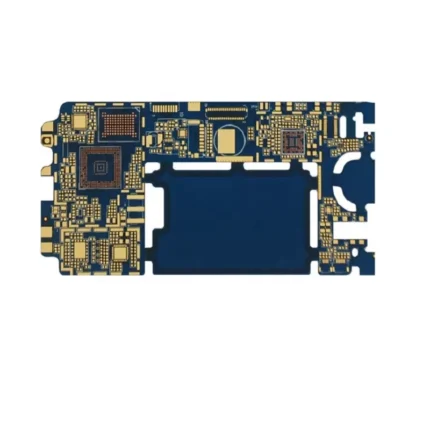

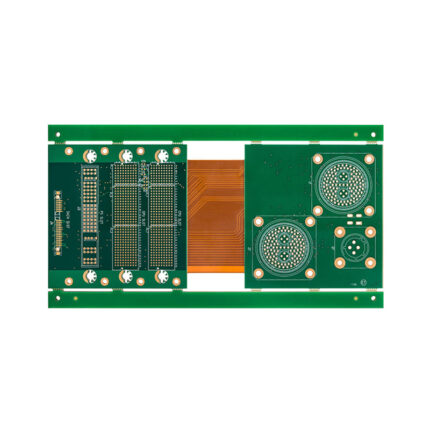

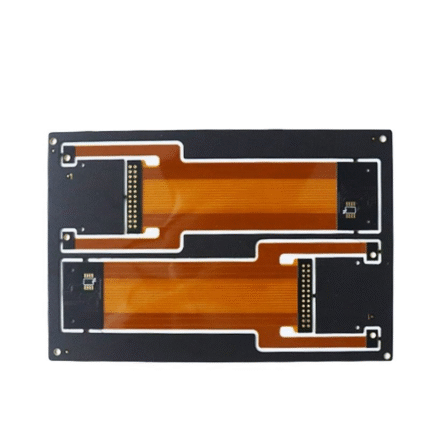

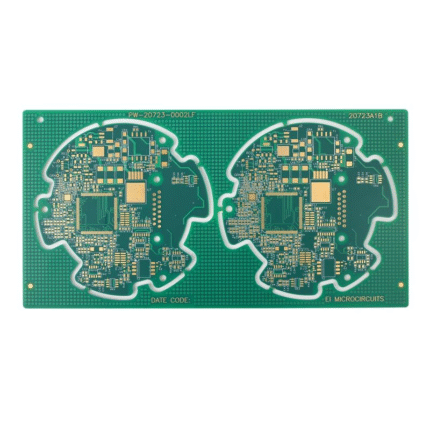

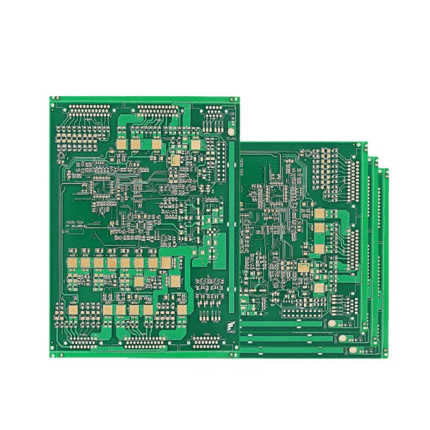

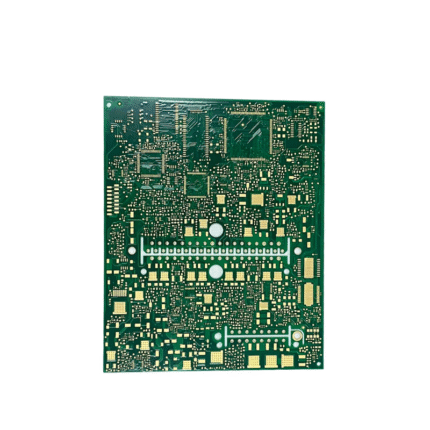

Flex PCBs represent the cutting edge of interconnect technology, offering unparalleled design freedom and reliability for modern electronic applications. These innovative circuits are engineered to bend, fold, and flex while maintaining exceptional electrical performance, making them ideal for space-constrained and dynamic applications where traditional rigid boards would fail. Our Flex PCBs are manufactured using premium polyimide materials that withstand repeated flexing cycles without compromising functionality.

Enabling Next-Gen Designs in Electronics, Automotive, and Beyond

The unique properties of Flex PCBs enable revolutionary product designs across multiple industries. In consumer electronics, they allow for foldable smartphones and ultra-thin wearable devices. Medical applications benefit from their ability to conform to body contours in implantable devices and diagnostic equipment. Automotive systems utilize Flex PCBs in tight spaces where vibration resistance is crucial, while aerospace applications take advantage of their weight-saving potential. The technology is particularly valuable for IoT devices, where compact form factors and reliable connections are paramount.

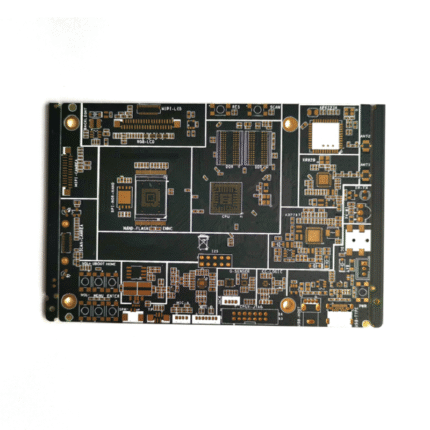

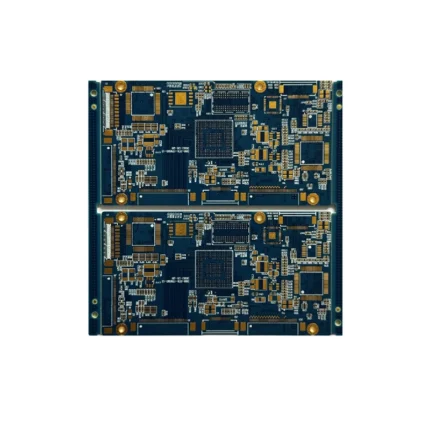

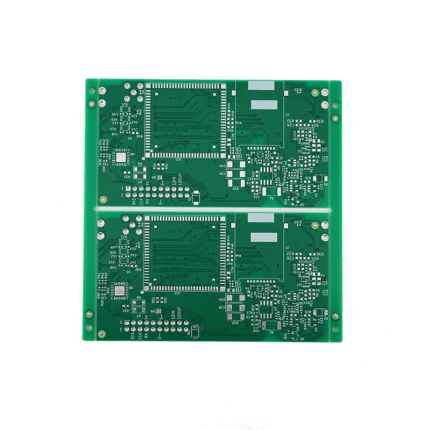

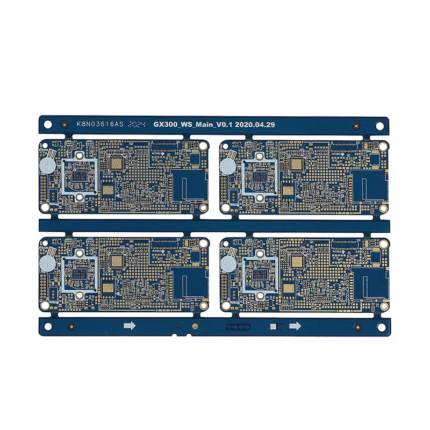

From Microvias to Final Inspection—Quality at Every Step

Our manufacturing process ensures each Flex PCB meets the highest quality standards. We use advanced laser drilling technology to create microvias as small as 25μm, enabling high-density interconnects in multilayer designs. The polyimide substrates we select offer excellent thermal stability, with continuous operating temperatures up to 200°C. For enhanced durability, we offer adhesiveless laminates that reduce thickness while improving thermal performance. Every Flex PCB undergoes rigorous testing, including automated optical inspection (AOI) and electrical continuity testing, to guarantee reliability in the field.

Key advantages of our Flex PCBs include

Space savings of up to 60% compared to traditional wiring harnesses

Weight reduction potential exceeding 70% versus rigid PCB alternatives

Dynamic flex endurance exceeding 1 million cycles for moving applications

Superior resistance to vibration and mechanical stress

Customizable stackups for optimal signal integrity in high-speed designs

Our Flex PCBs are manufactured in ISO 9001-certified facilities using state-of-the-art equipment.

The production process includes

– Precision laser cutting of polyimide substrates- Electrolytic copper plating for consistent thickness

– High-resolution photolithography for fine features

– Controlled impedance routing for RF applications

– Automated optical inspection at multiple stages

– Electrical testing with flying probe systems

– Final verification of flex endurance properties

Reviews

There are no reviews yet.