Mastering Hybrid Assembly Complexity

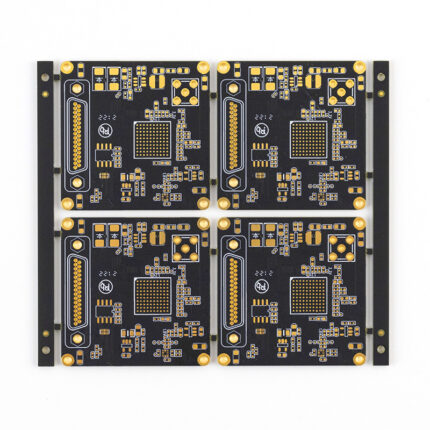

- As a 13-year certified PCBA manufacturer, we transform bare boards into market-ready products with full-system integration capabilities. Our turnkey services cover:

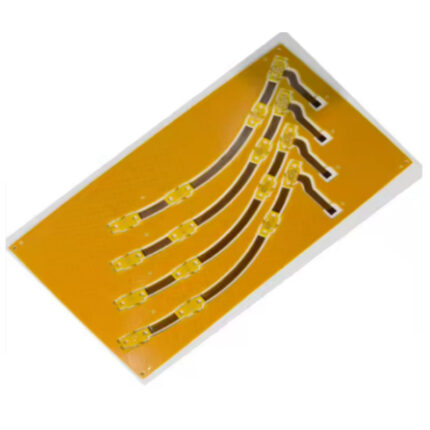

- Electro-Mechanical Assembly: Precision mounting of PCBAs, connectors, wiring harnesses, displays, and enclosures (metal/plastic/silicone).

- Firmware & Functional Testing: In-house programming (ICSP/JTAG) and system-level validation (EMC, drop, thermal cycling).

- Supply Chain Consolidation: Single-source procurement for 2000+ components, reducing logistics costs by 25–40%.

- Supported by automated guided vehicles (AGV) and barcode-tracked assembly lines for zero-mistake builds.

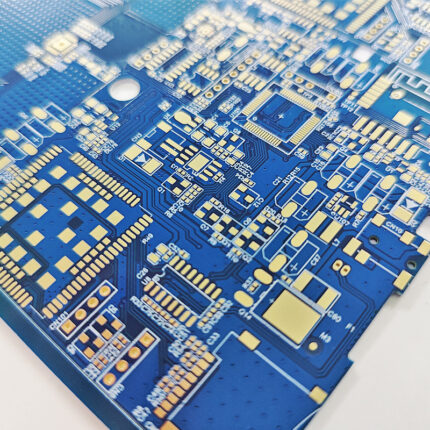

Zero-Defect Final Assembly

In-process Verification: Real-time torque monitoring for screw fastening (±5% tolerance), IPC-A-620-compliant cable routing.

Environmental Stress Screening (ESS): 48-hour burn-in at 85°C/85% RH for automotive/medical products.

Sealing & IP Rating Validation: IP67 testing with 1m submersion (per IEC 60529).

Certifications: ISO 13485 (medical), IATF 16949 (automotive), CCC

Traceability: Component-level data logging (batch, date, test results) accessible via cloud portal.

Industry-Proven Integration

Medical Devices:

Cleanroom assembly (Class 8) with ESD protection

Biocompatible sealing for implantable housings

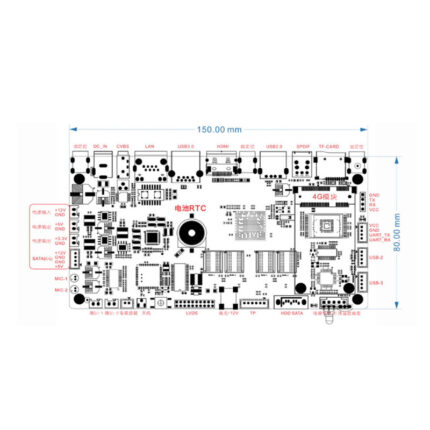

Industrial IoT:

DIN-rail mounting & conformal coating for harsh environments

Wireless module (BLE/WiFi 6) pre-pairing

Consumer Electronics:

Snap-fit design for tool-less disassembly (TCO reduction)

Cosmetic defect control (<0.1% scratch rate)

Case: 50K-unit smart meter project – 99.95% on-time delivery with 0 field returns.

Reviews

There are no reviews yet.