Ready to Transform Your Design? Let’s Talk Rigid-Flex

The production of Rigid-Flex PCBs requires specialized expertise in material selection, stackup design, and manufacturing process control. Our engineering team works closely with clients to optimize designs for manufacturability, ensuring reliable performance while controlling costs. We offer design for manufacturability (DFM) reviews, signal integrity analysis, and thermal modeling to validate designs before production begins.

Whether you need simple Rigid-Flex boards for cost-sensitive applications or complex multilayer designs for mission-critical systems, our solutions deliver unmatched reliability in demanding environments. The combination of rigid and flexible technologies enables innovative product designs that would be impossible with conventional PCBs, while providing improved durability and reduced assembly complexity. Contact us today to discuss how Rigid-Flex PCB technology can solve your most challenging electronic packaging requirements.

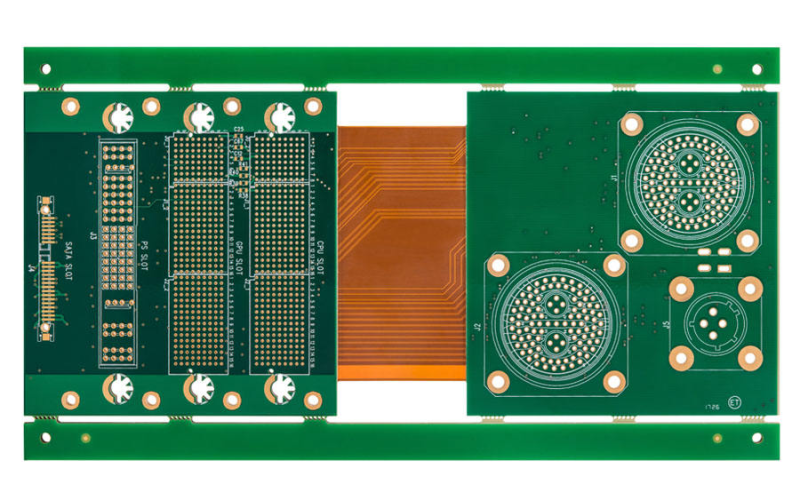

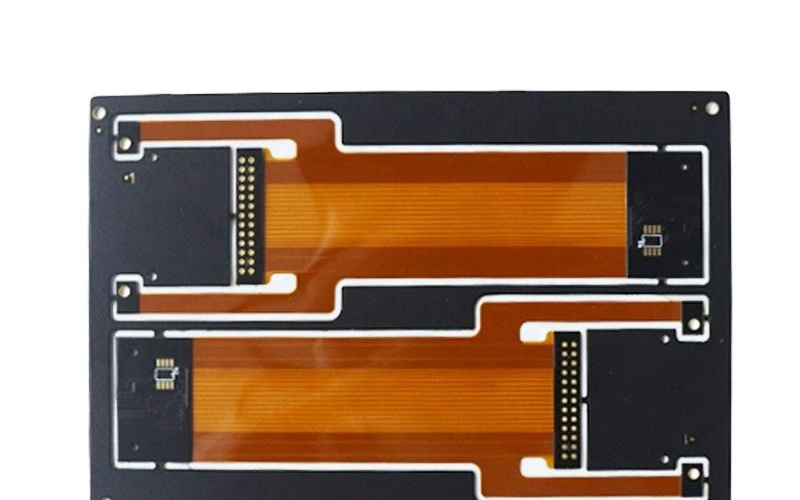

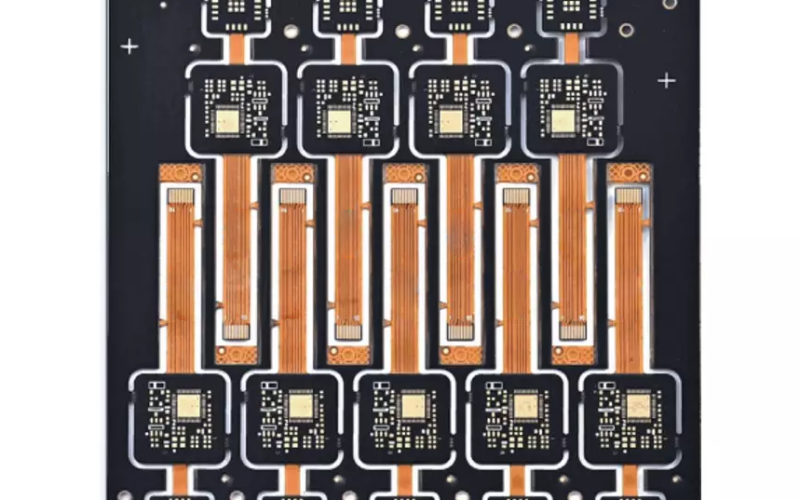

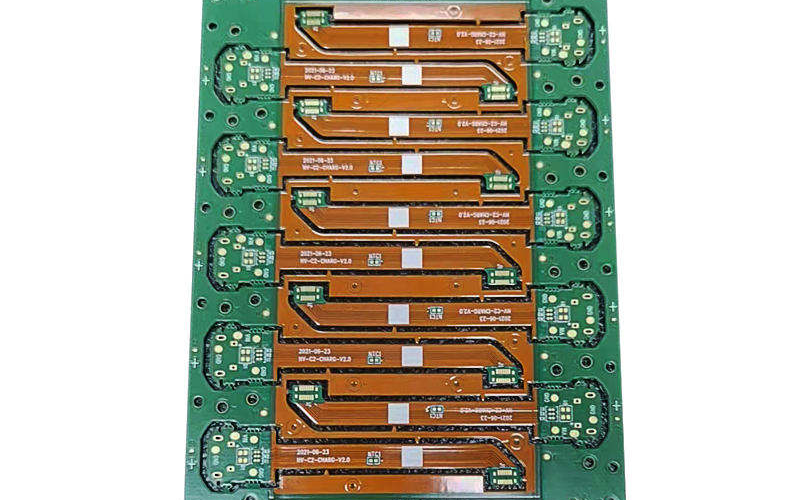

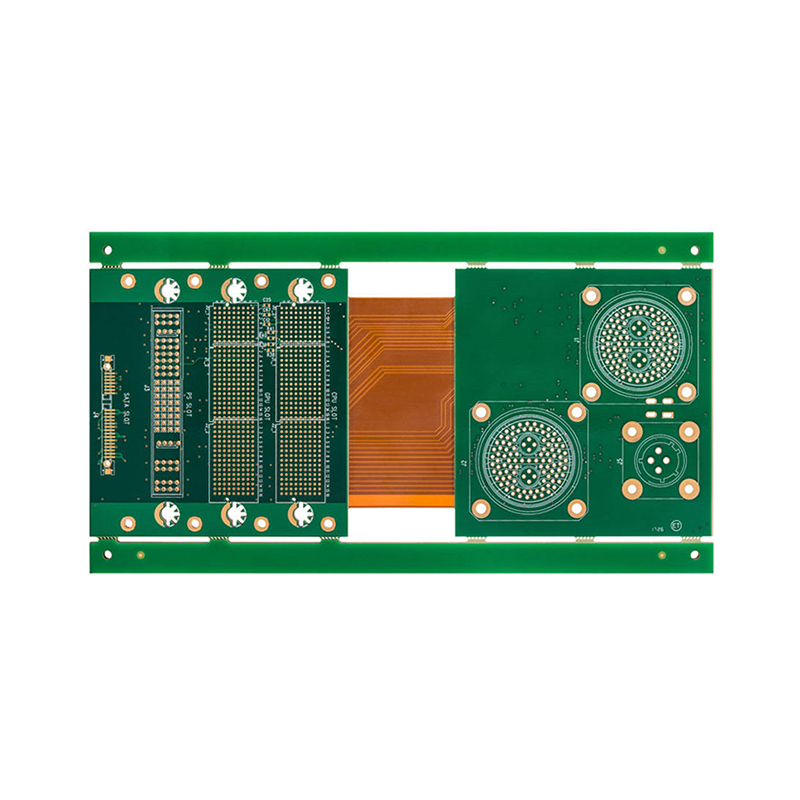

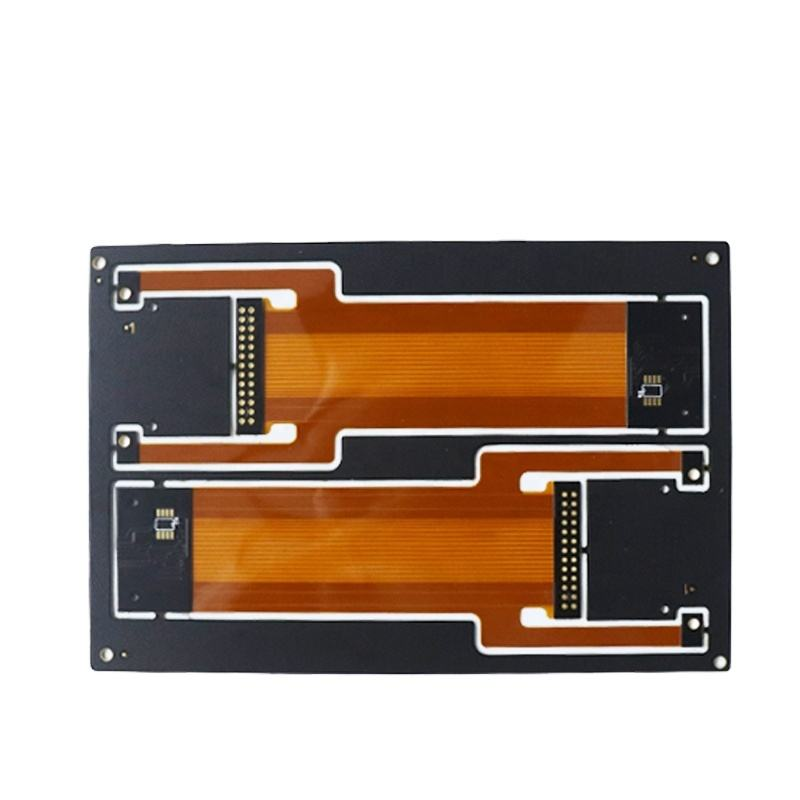

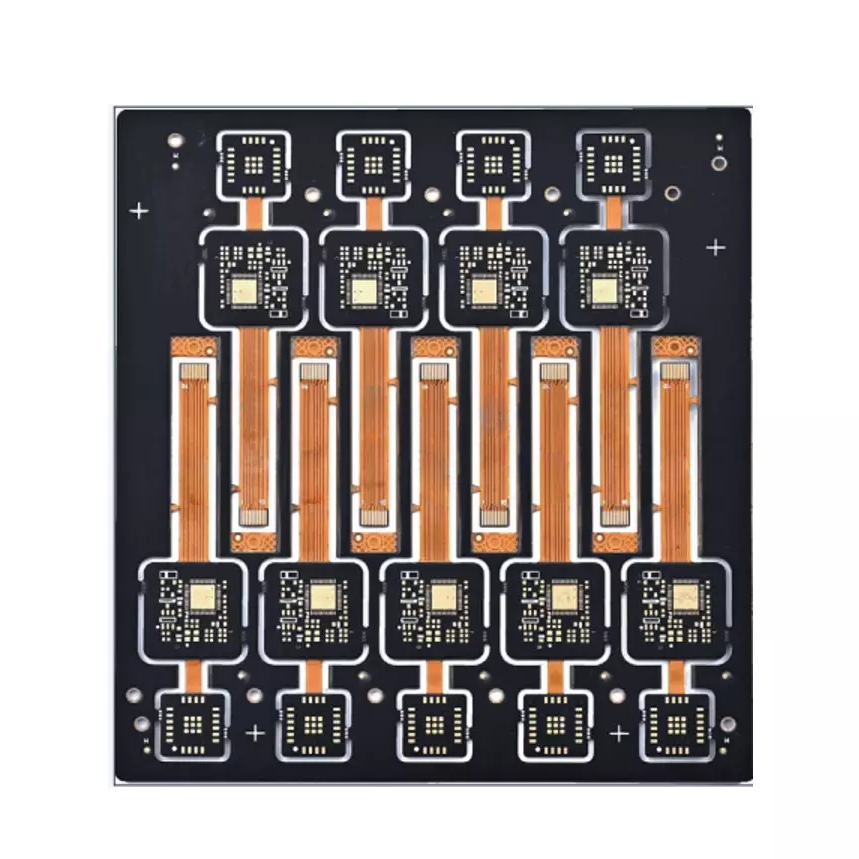

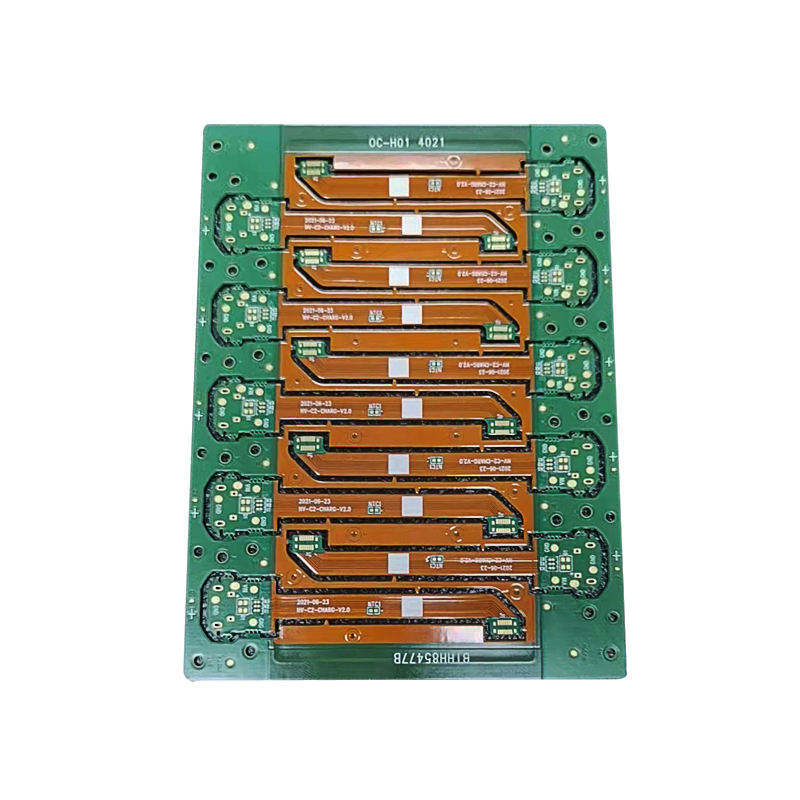

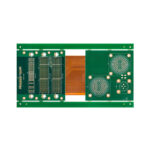

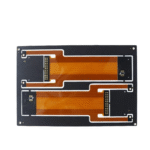

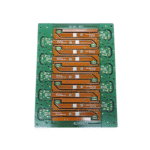

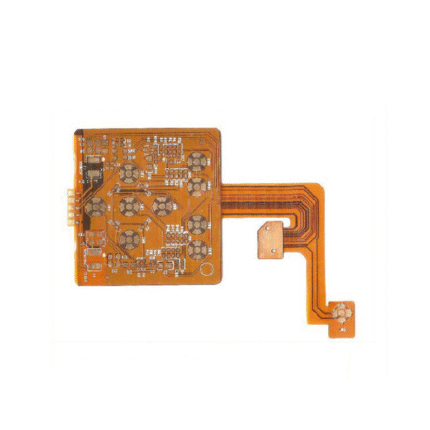

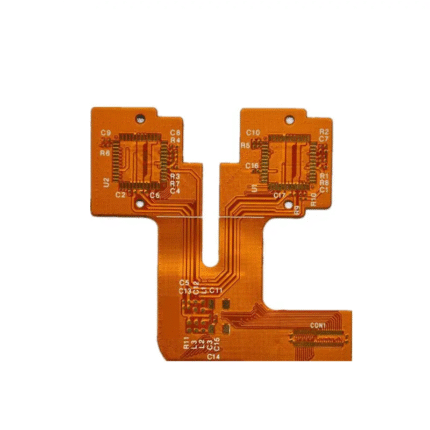

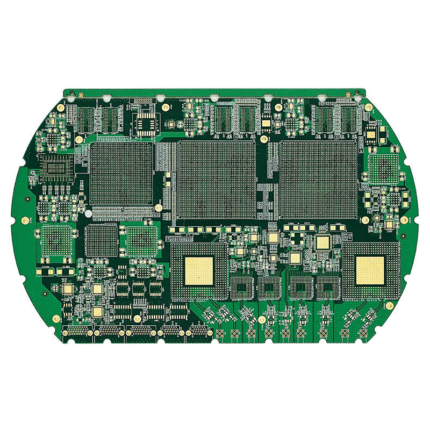

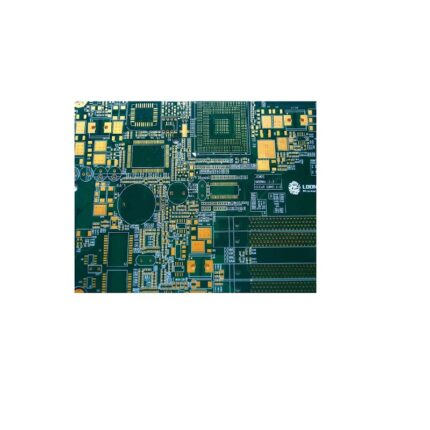

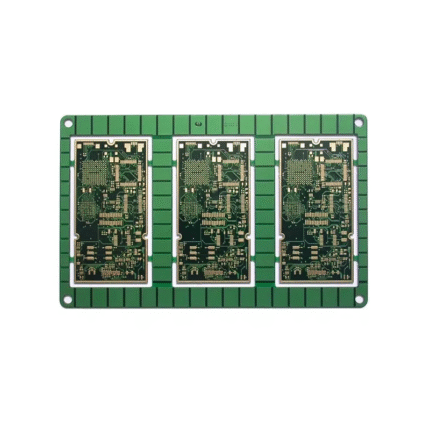

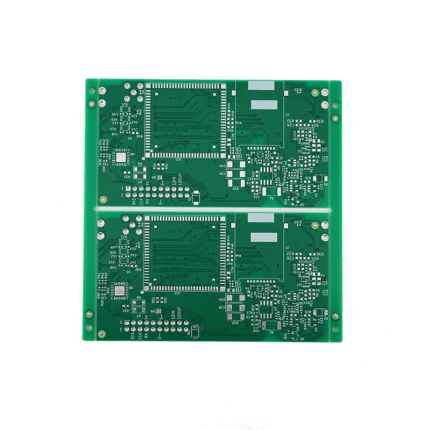

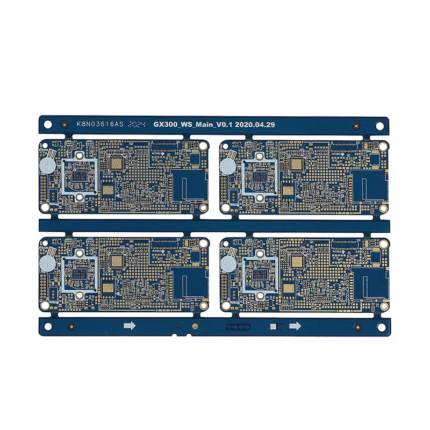

High-Reliability Rigid-Flex PCBs with Polyimide Flex and FR4 Rigid Sections

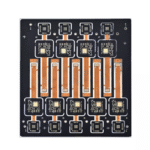

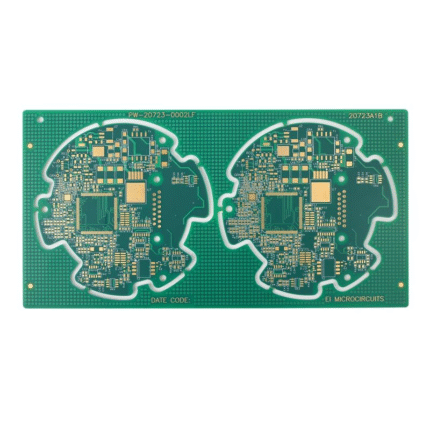

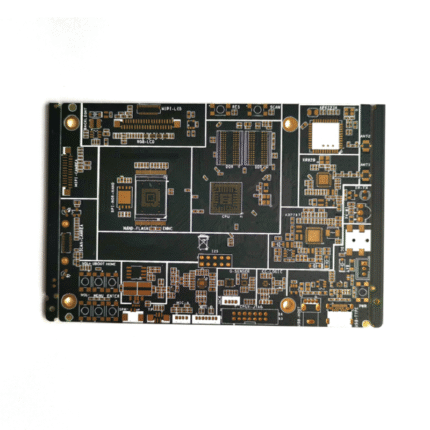

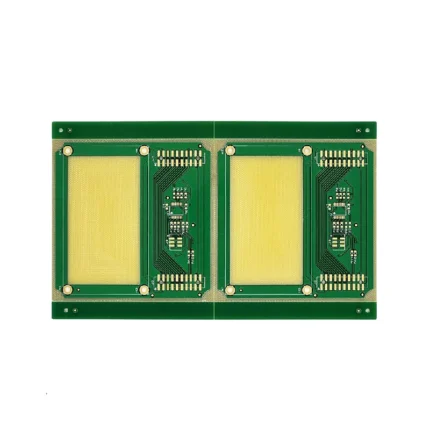

Rigid-Flex PCBs represent the pinnacle of printed circuit board technology, combining the structural stability of rigid boards with the flexibility of dynamic circuits in a single, integrated package. These hybrid circuits eliminate the need for connectors and cables between board sections, creating more reliable, compact, and lightweight electronic assemblies. Our Rigid-Flex PCBs are engineered to meet the most demanding applications where space constraints, reliability under stress, and complex three-dimensional packaging are critical factors.

Rigid-Flex PCBs: Powering Tomorrow’s Technologies

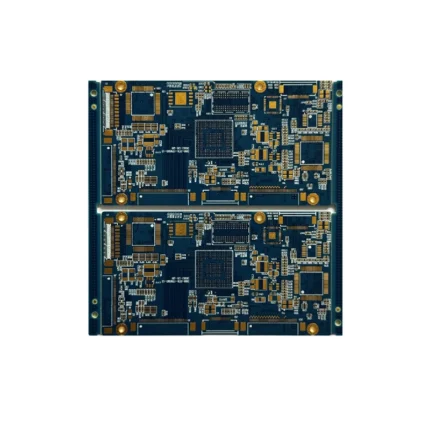

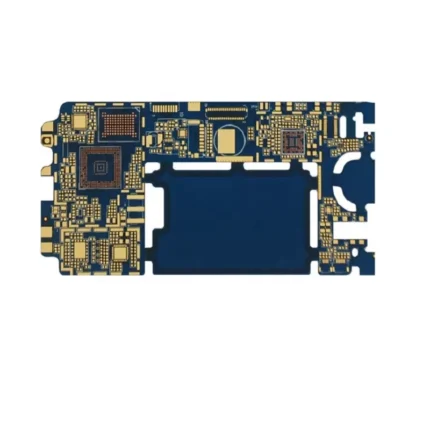

The unique architecture of Rigid-Flex PCBs makes them indispensable across multiple high-tech industries. In aerospace and defense applications, they provide vibration-resistant interconnections for avionics systems while reducing weight. Medical devices utilize Rigid-Flex technology for compact, reliable imaging equipment and surgical tools. The automotive sector benefits from their durability in engine control units and advanced driver assistance systems (ADAS). Consumer electronics manufacturers leverage Rigid-Flex designs for foldable devices, wearables, and space-saving solutions where conventional PCBs would be impractical.

Advanced Materials, Smarter Design: The Rigid-Flex Advantage

Our Rigid-Flex PCBs are manufactured using a proprietary process that ensures seamless integration between rigid and flexible sections. We use high-performance polyimide materials for the flexible layers, providing excellent thermal stability and mechanical endurance. The rigid sections typically employ FR4 or high-frequency laminates, depending on application requirements. Special attention is given to the transition zones between rigid and flexible areas, where we implement reinforced structures to prevent delamination and ensure long-term reliability.

Our Advanced Rigid-Flex PCB Manufacturing Process Includes:

Laser Microvia Drilling (75μm)

Sequential Lamination of rigid and flexible layers

Controlled Depth Drilling for precise connections

Automated Optical Inspection (AOI) at each stage

3D Form Testing for folding and bending performance

Cross-Section Analysis to ensure build quality

Electrical Testing with custom fixtures

Environmental Stress Testing (thermal & humidity)

Reviews

There are no reviews yet.