Key advantages of our Aluminum PCB technology include:

– Superior thermal management for high-power density designs

– Enhanced mechanical stability and vibration resistance

– Weight reduction compared to traditional heatsink solutions

– Improved thermal cycling performance (up to 1000 cycles)

– UL94 V-0 flammability rating for safety compliance

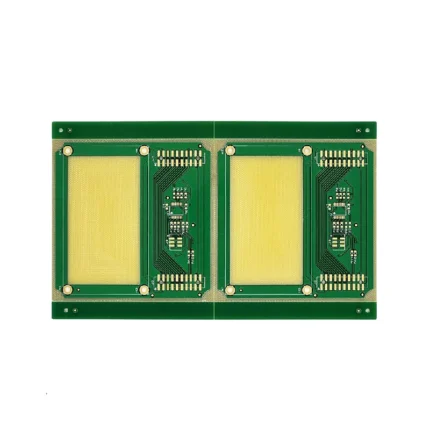

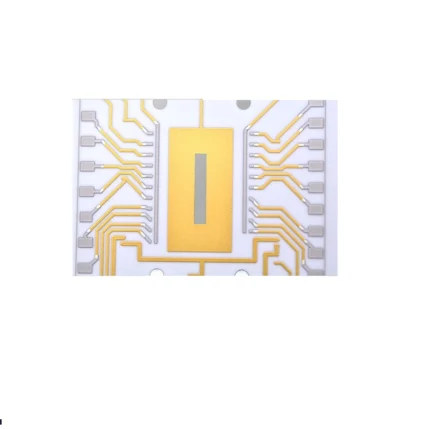

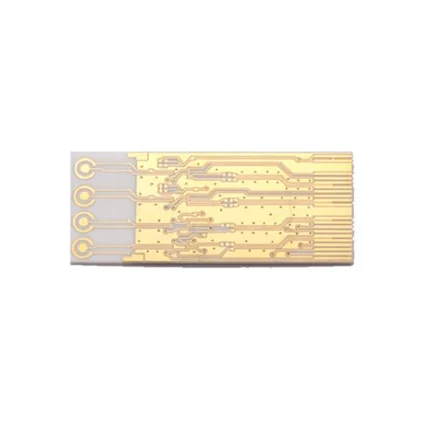

Surface finish options are carefully selected for optimal thermal and electrical performance:

– HASL (Hot Air Solder Leveling) for cost-effective solutions

– ENIG (Electroless Nickel Immersion Gold) for wire bonding applications

– Immersion Silver for high-frequency power devices

– OSP (Organic Solderability Preservative) for lead-free assemblies

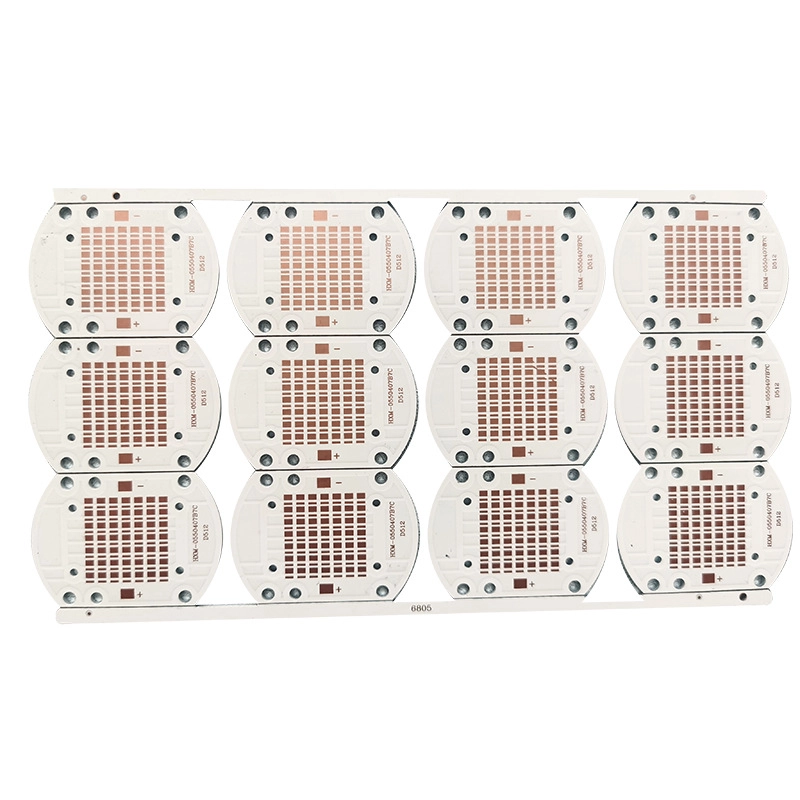

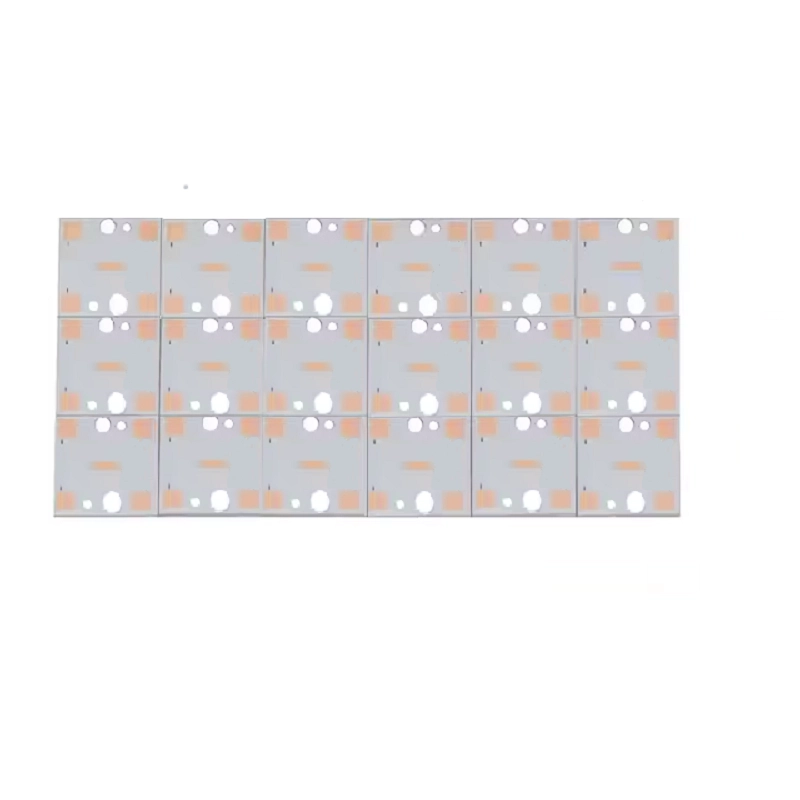

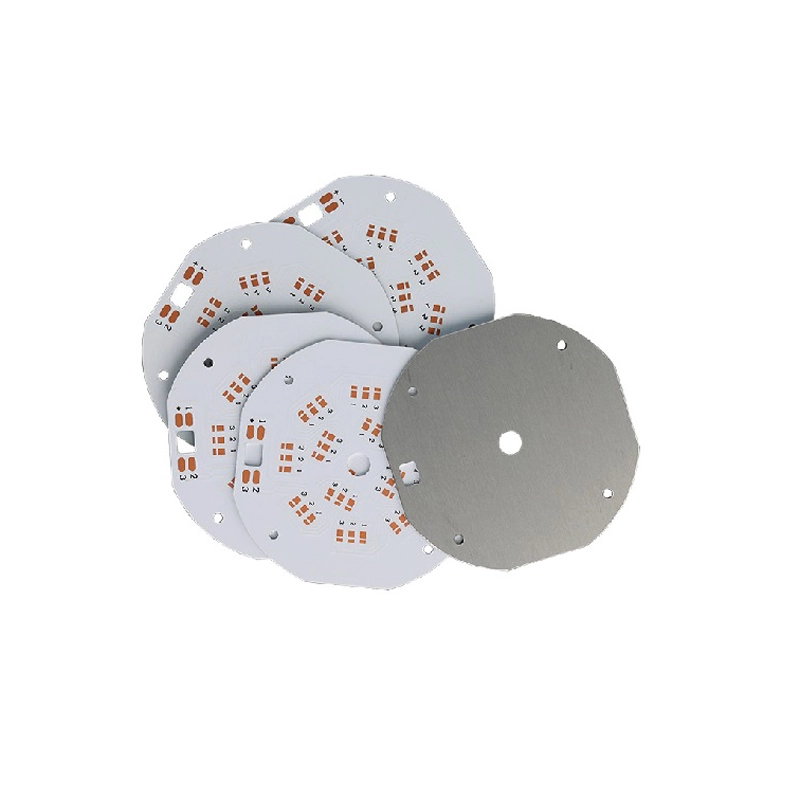

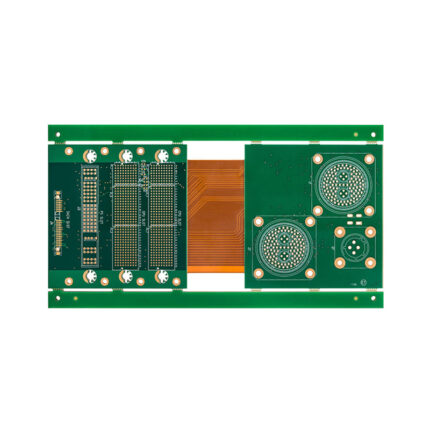

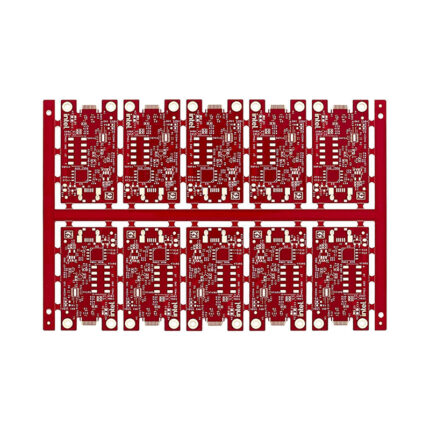

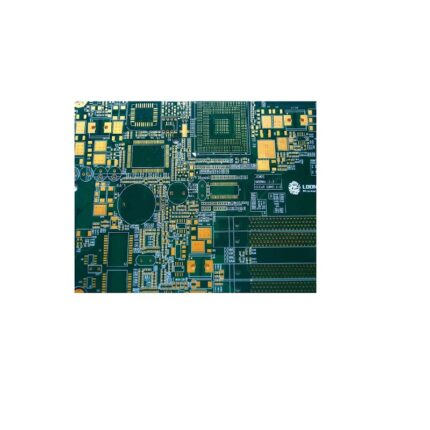

Our advanced manufacturing process for Aluminum PCBs incorporates several critical technologies:

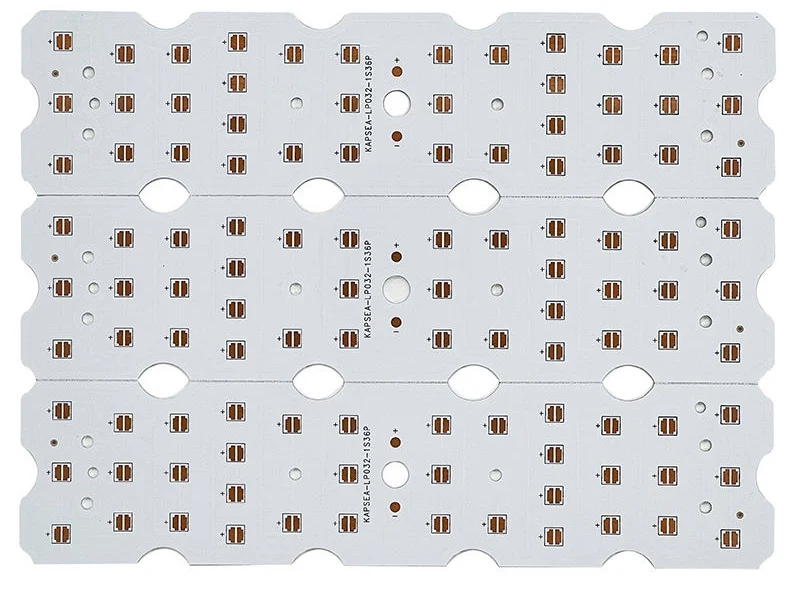

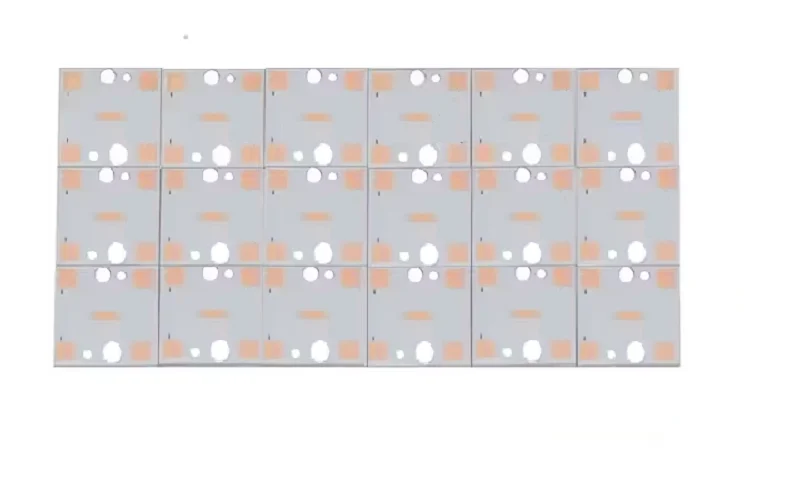

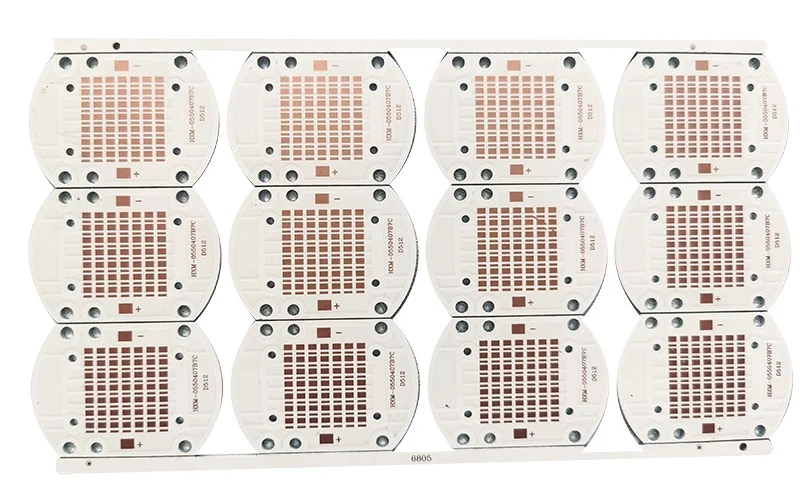

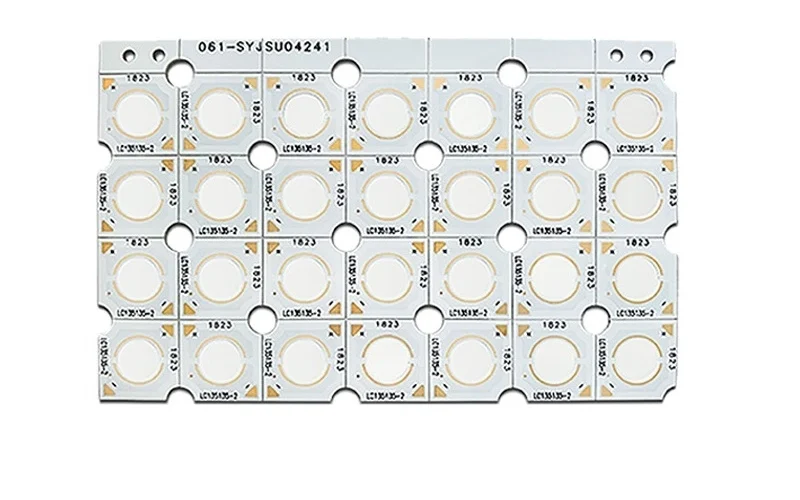

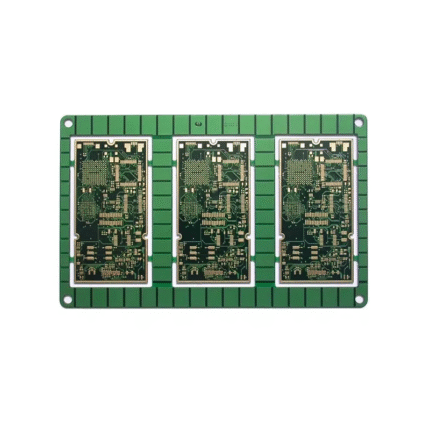

– Precision routing and V-scoring for aluminum core boards

– Thermal conductivity testing for dielectric layer verification

– Laser ablation for precise via formation in thermal pads

– Automated optical inspection (AOI) for copper pattern verification

– Thermal stress testing per IPC-TM-650 standards

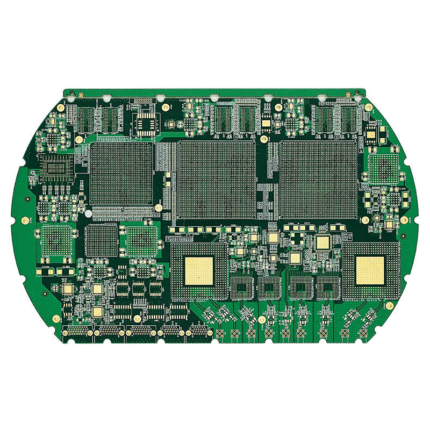

Quality assurance measures include:

– 100% electrical testing including high-voltage isolation checks

– Thermal impedance measurement using standardized methods

– Cross-section analysis for dielectric layer integrity

– Thermal cycling tests between -40°C to +150°C

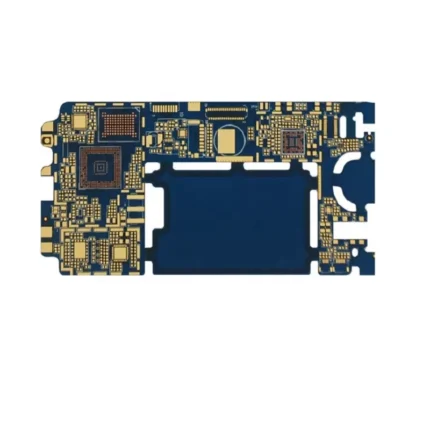

Common applications benefiting from Aluminum PCB technology:

– LED lighting systems (street lights, grow lights, automotive lighting)

– Power conversion equipment (inverters, converters, UPS systems)

– Automotive electronics (headlight systems, battery management)

– Industrial power devices (motor drives, power supplies)

– Renewable energy systems (solar inverters, wind power converters)

Reviews

There are no reviews yet.