Mastering Hybrid Assembly Complexity

“With 13 years of solving mixed-technology challenges, we bridge the gap between high-density SMT and robust THT requirements.

Our IPC-certified engineers leverage dual-process expertise to conquer.”

Thermal Conflict Resolution – Preventing reflow damage to through-hole components

Selective Soldering Precision – 0.1mm nozzle accuracy for SMT/THT coexistence zones

Material Compatibility – Optimizing solder pastes/fluxes for hybrid processes

Hybrid Assembly Technology Matrix

| Challenge | Our Solution | Technical Edge |

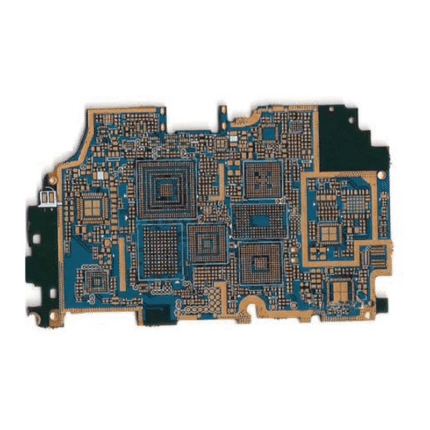

| High-Density + High-Power | SMT 01005 + 10oz copper THT | Thermal relief pads + stepped stencils |

| Fine-Pitch BGAs + Press-Fit | Bottom-side SMT + top-side force insertion | Dedicated no-clean flux chemistry |

| Flex-Rigid + Connectors | Sequential lamination + selective soldering | Fixture-less conveyor adaptation |

| Harsh Environment Boards | Conformal coating post dual-process | Robotic spraying with SMT mas |

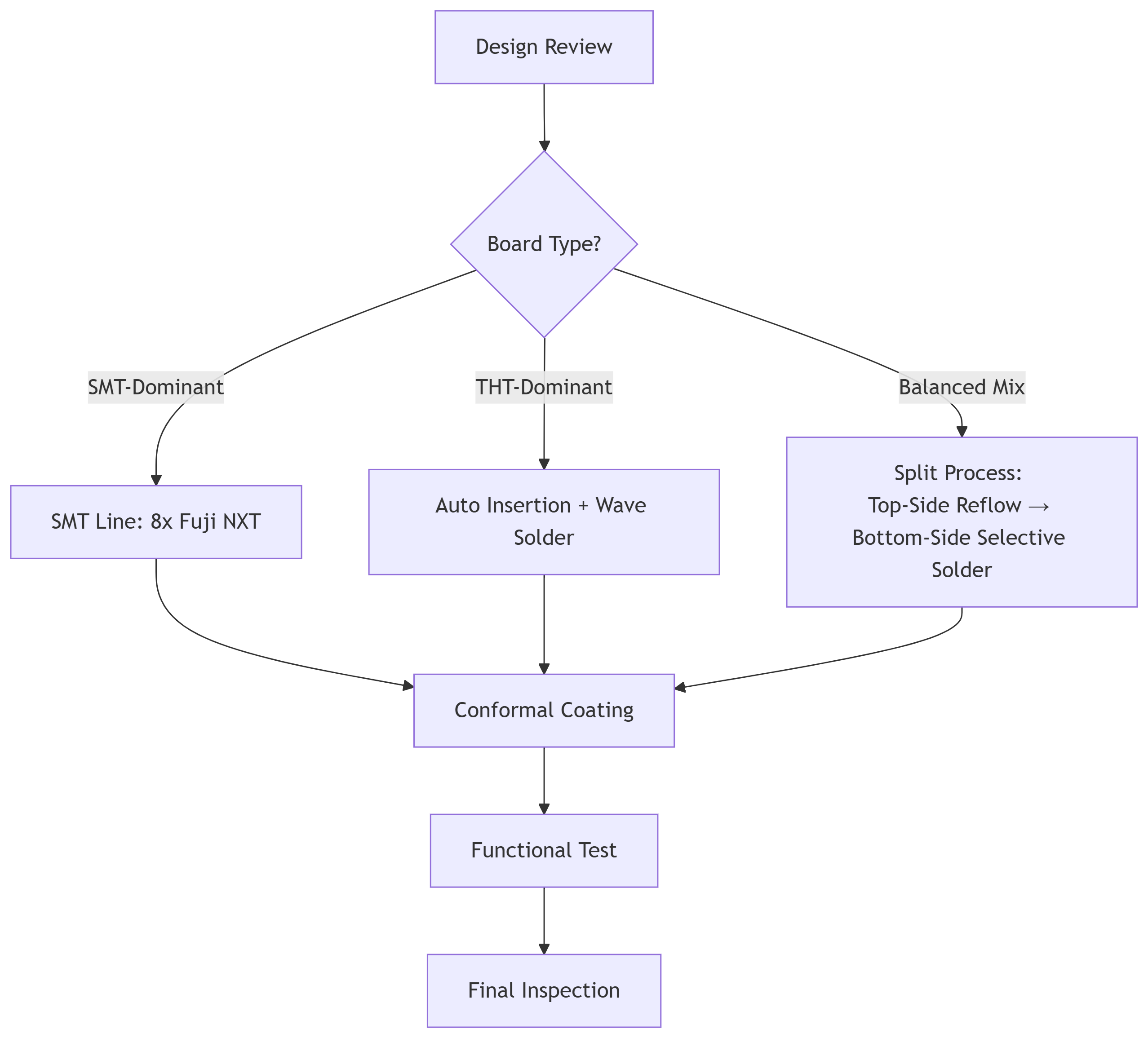

Integrated Production Flow

Hybrid Assembly Capability:

Equipment Synergy

SMT/THT Transition: ERP-controlled routing to 3x JBC selective soldering cells

Micro-Soldering: Manual rework stations with 40X magnification (for 0.3mm pitch)

Thermal Management: Nitrogen-inerted reflow ovens + directed convection preheat

Quality Control

Cross-Process AOI: Koh Young 3D inspection pre/post soldering

X-Ray Verification: BGA/through-hole fill analysis in single scan

Reliability Testing:

Thermal cycling (-55°C to +125°C)

Vibration testing (20-2000Hz per MIL-STD-810)

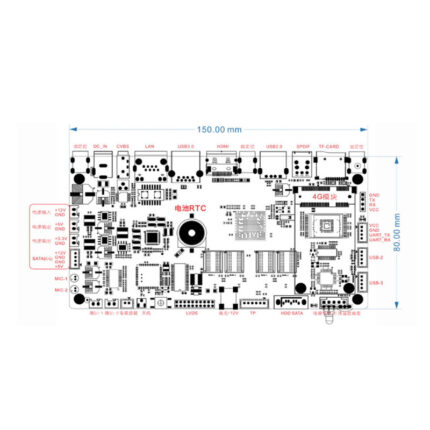

Industry-Proven Applications

| Sector | Case Example | Technology Mix |

| Medical Imaging | MRI Controller Boards | 24L HDI + 200-pin connectors + shielding cans |

| Industrial IoT | Rugged Edge Gateways | Bottom-side PoE magnetics (THT) + top-side 0.4mm BGAs |

| EV Power Systems | Battery Management Units (BMUs) | 10oz copper busbars + 01005 current sensors |

| Aerospace | Avionics Control Modules | Flex-rigid + hermetic connectors + IPC Class 3 |

Hybrid Technology Advantages

Cost Efficiency

30% reduced NPI cycles via concurrent DFM/DFA analysis

Zero cross-contamination between SMT/THT zones

Quality Excellence

99.1% first-pass yield on mixed boards (vs industry avg 96.3%)

Component-level traceability across both processes

Scalability

Prototype to 50k/month volume without line changeover

Dynamic workcell allocation for rush orders

Certified Hybrid Assembly Ecosystem

[ISO 9001:2015] [IATF 16949] [AS9100D] [ISO 13485]

Compliance: IPC-A-610 Class 3, IPC-J-STD-001, IPC-7711/21 Rework

Reviews

There are no reviews yet.