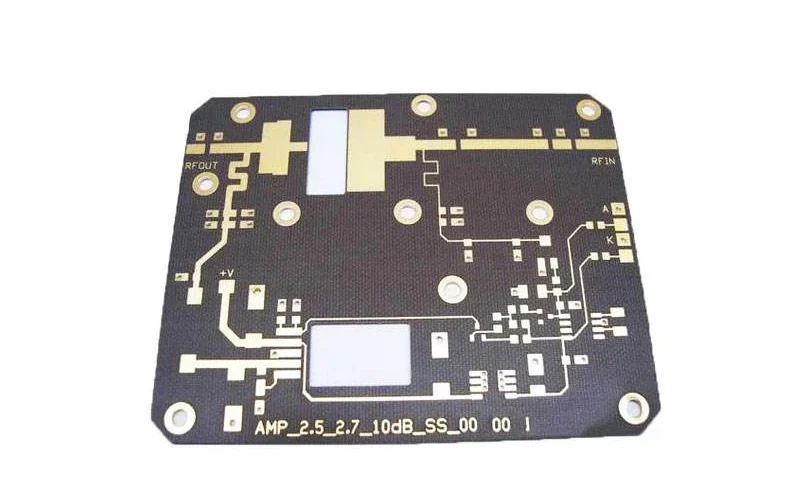

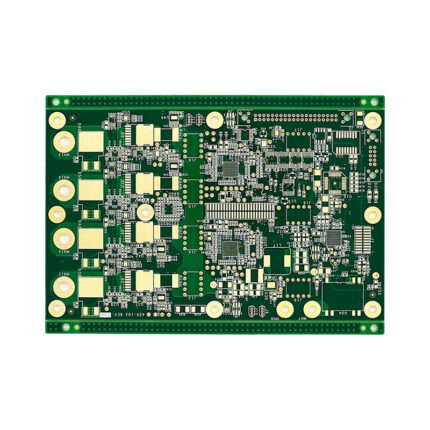

Rogers PCBs: The Benchmark for High-Frequency Performance

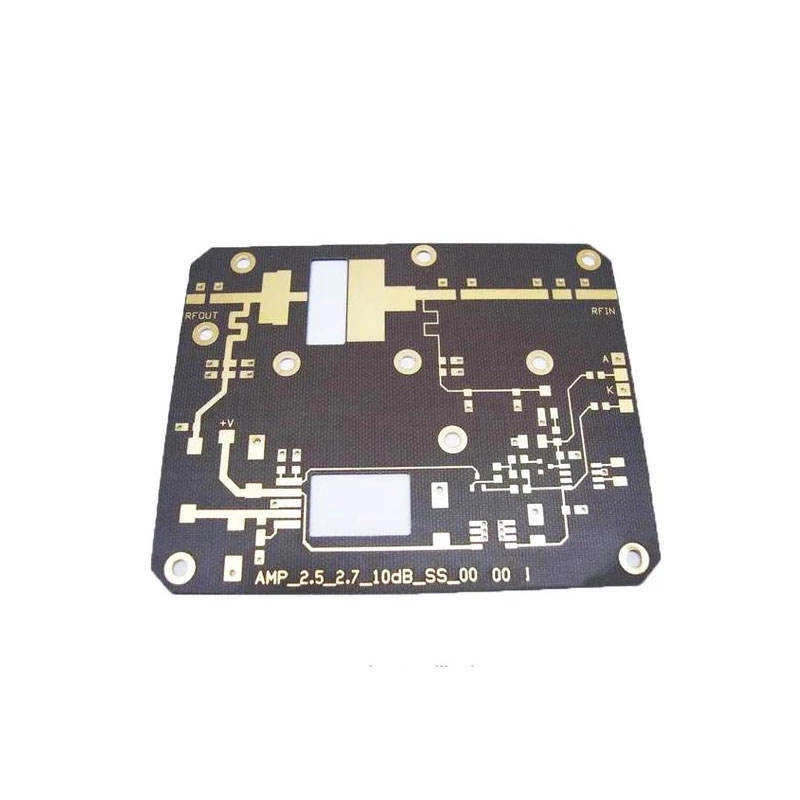

Rogers PCBs represent the gold standard for high-frequency electronic applications, offering superior electrical performance and unmatched signal integrity in RF, microwave, and high-speed digital circuits. Unlike conventional FR-4 materials, Rogers high-frequency laminates are engineered specifically to meet the demanding requirements of advanced wireless communication systems, aerospace and defense electronics, automotive radar systems, and satellite technology. With ultra-low dielectric loss (Df as low as 0.001) and stable dielectric constant (Dk from 2.2 to 10.2), Rogers PCBs minimize signal attenuation and maintain consistent performance even in extreme environments.

Material Advantages of Rogers PCBs

The core strength of Rogers PCBs lies in their advanced material composition. These high-performance substrates are engineered using:

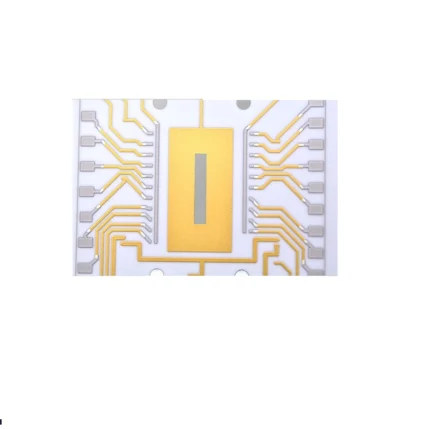

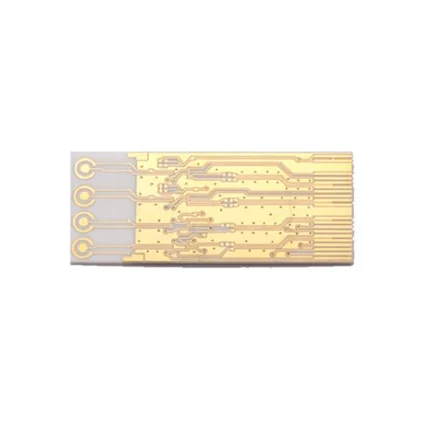

Ceramic-filled PTFE (Polytetrafluoroethylene)

Hydrocarbon ceramic formulations

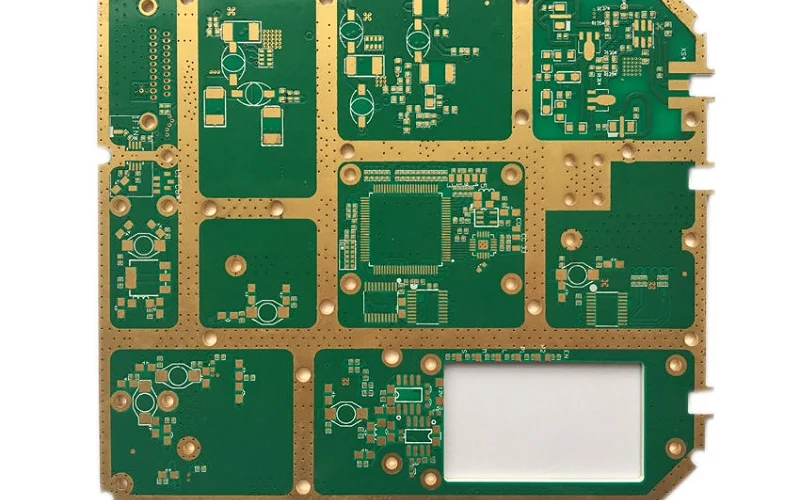

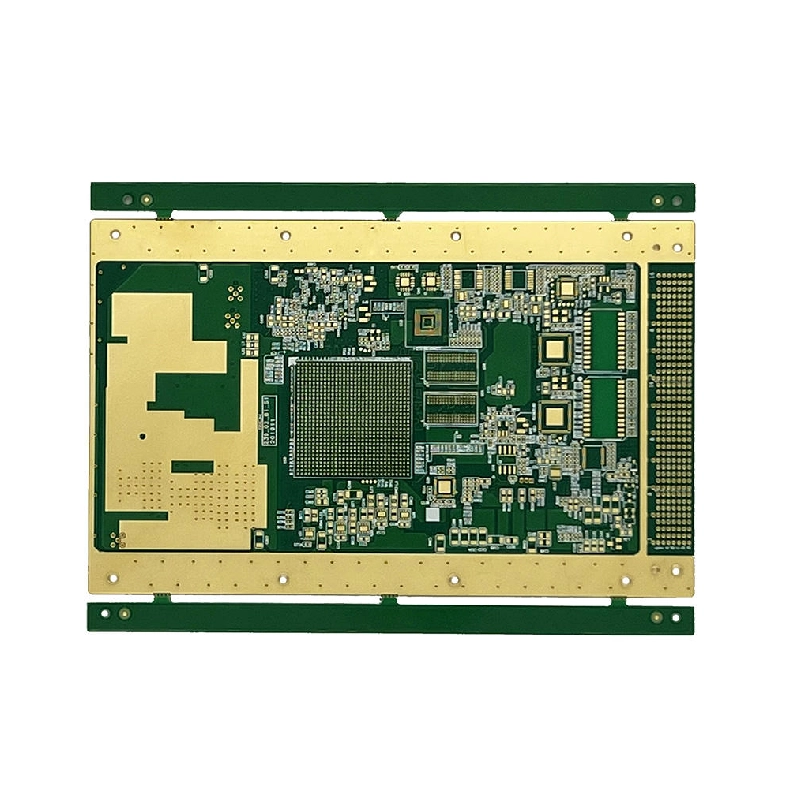

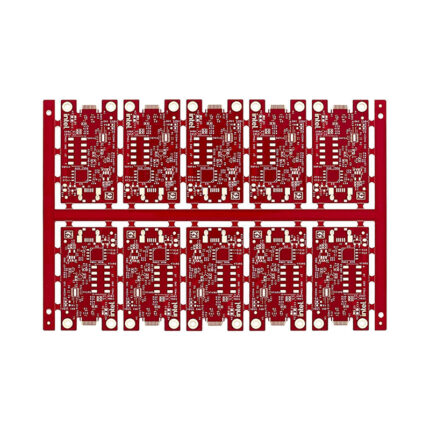

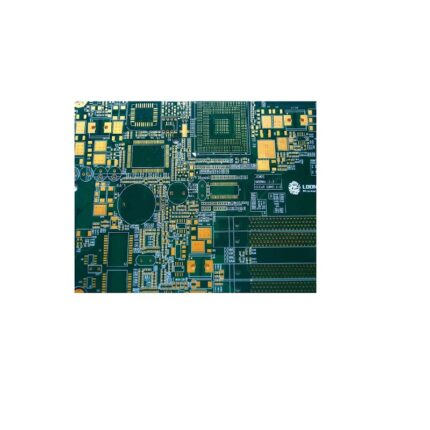

Comprehensive Rogers PCB Manufacturing Capabilities

Material Thickness Range

From 0.005″ to 0.250″

Supports applications from thin RF layers to robust multilayer boards

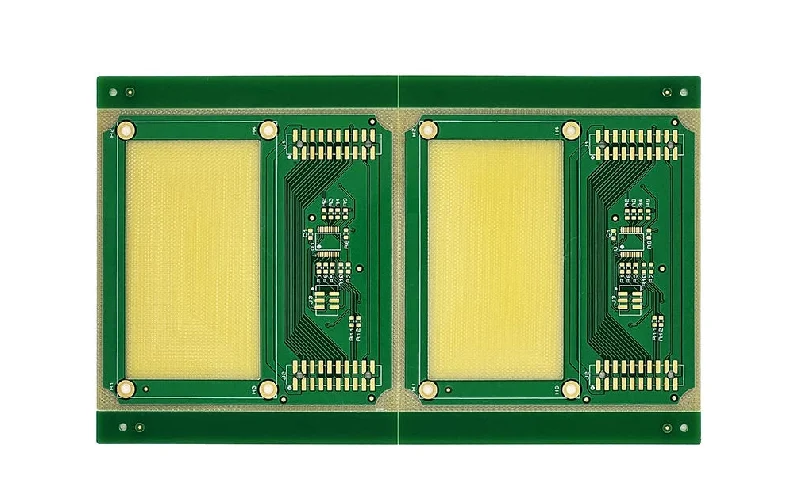

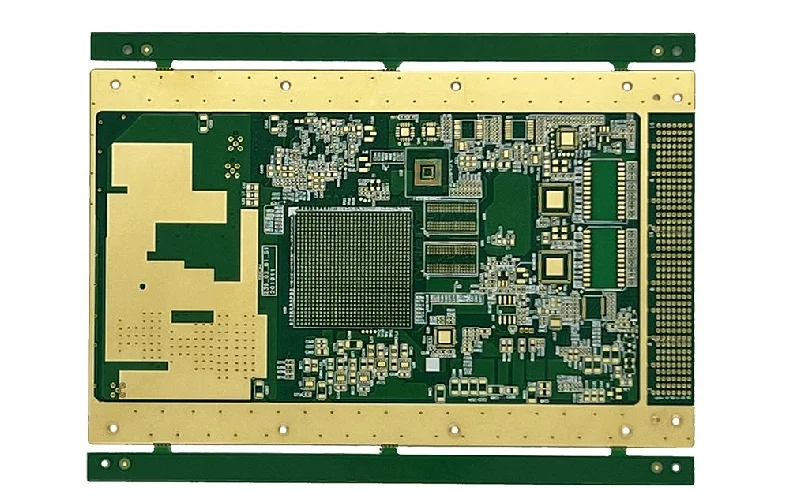

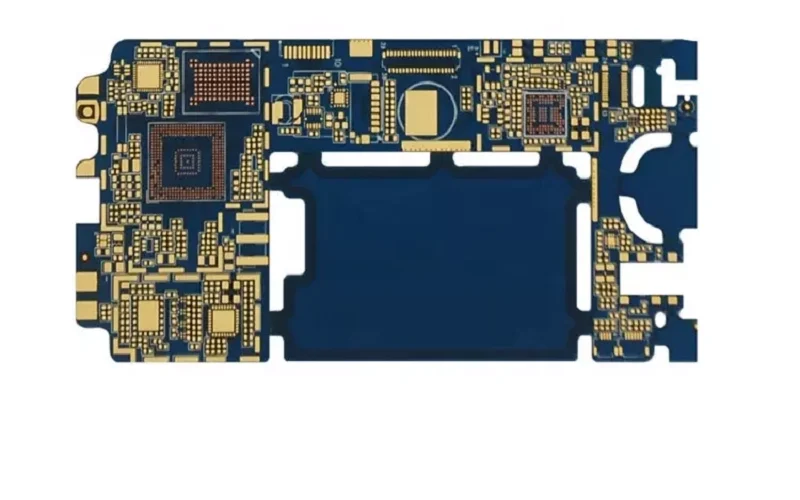

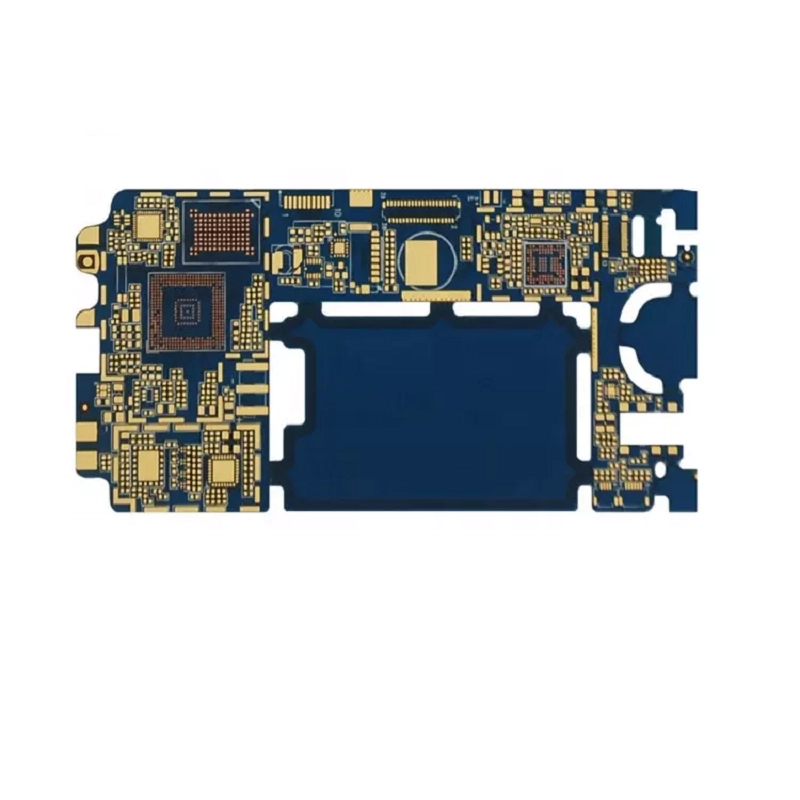

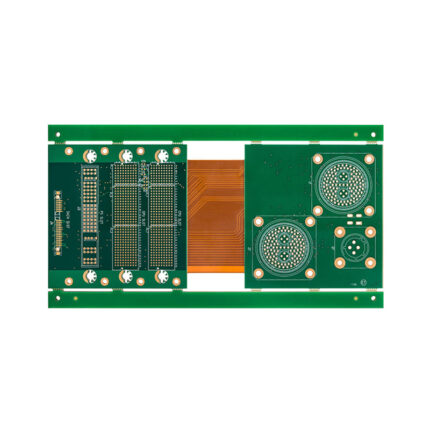

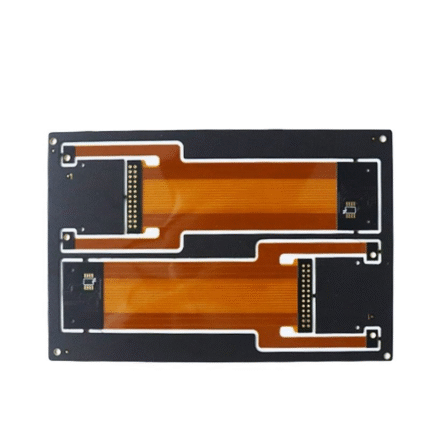

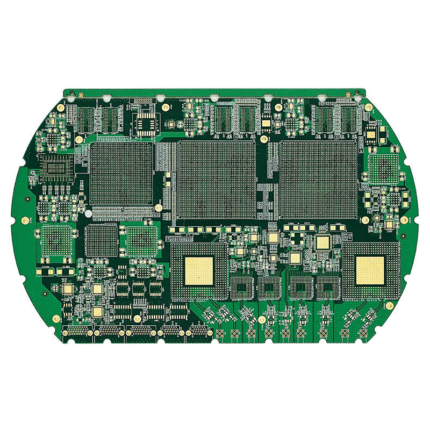

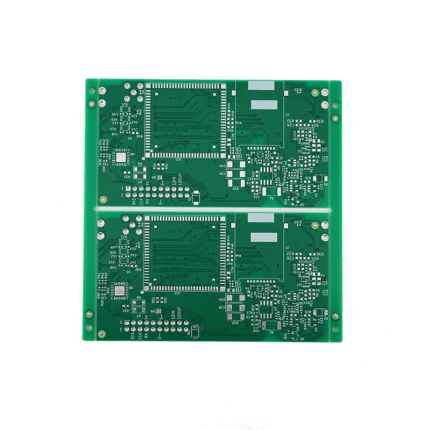

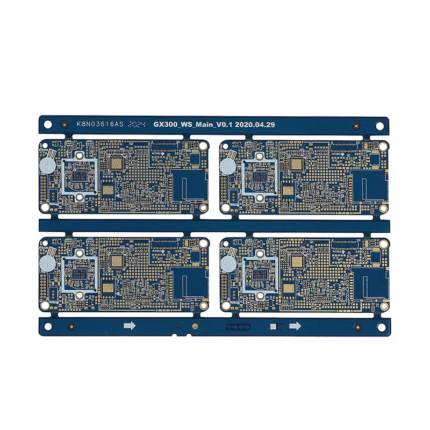

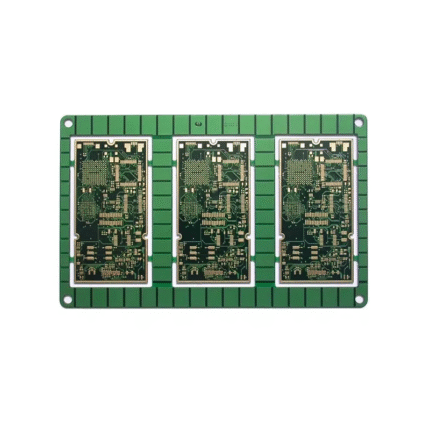

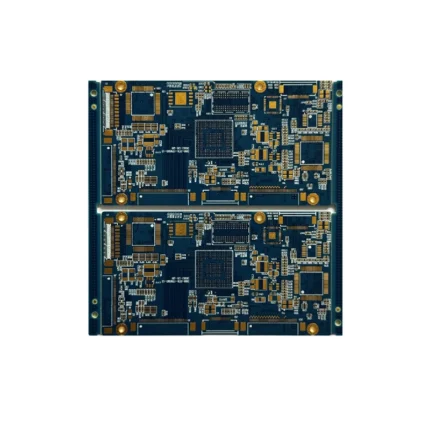

Layer Count & Construction

From 2-layer simple designs to 24-layer complex multilayer stack-ups

Suitable for hybrid builds combining Rogers with FR-4 for cost optimization

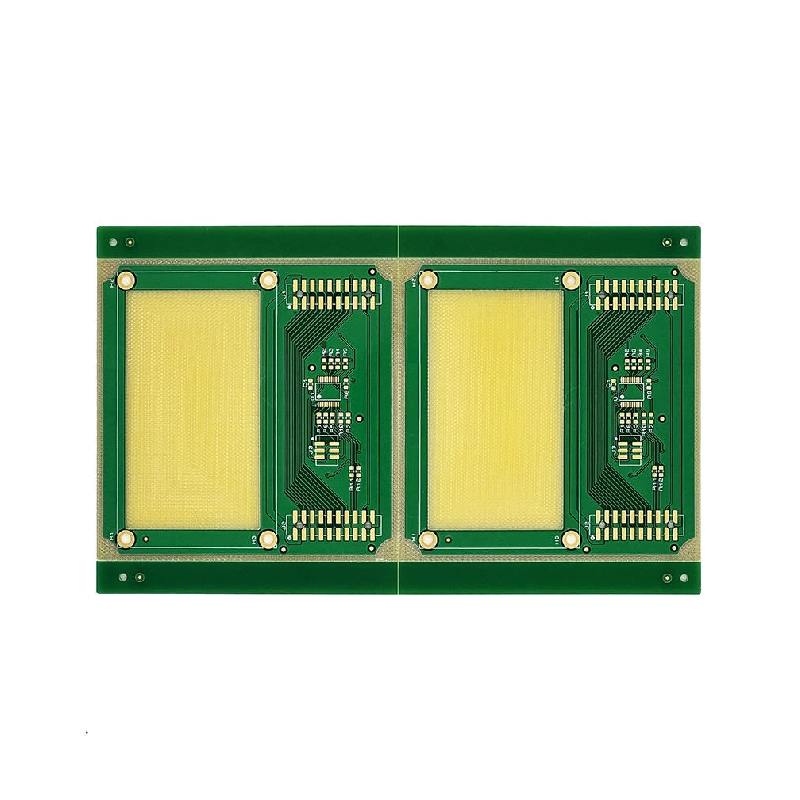

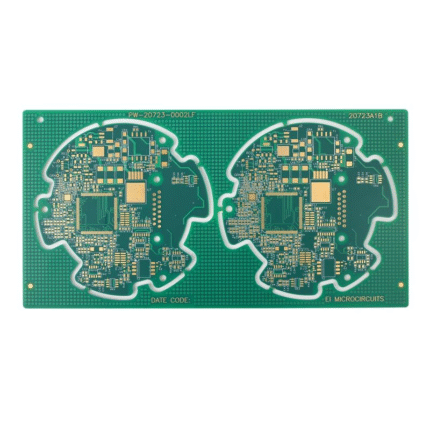

Panel Size & Tolerances

Maximum panel size: 18″ × 24″ (457mm × 610mm)

Thickness tolerance: ±3% standard, tighter available upon request

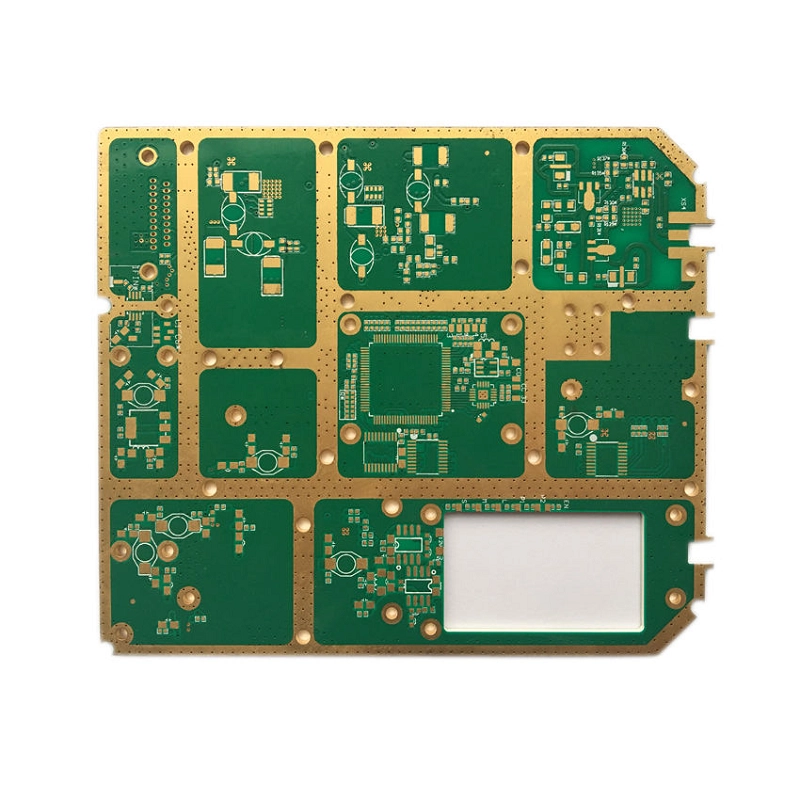

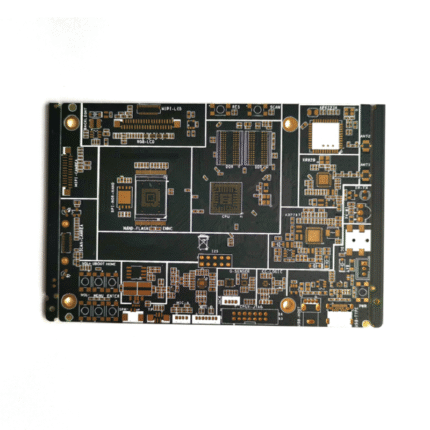

Specialized Rogers PCB Manufacturing Process

– Laser ablation for precision via formation in high-frequency materials

– Plasma treatment for optimal surface preparation and adhesion

– Automated optical inspection (AOI) with enhanced RF defect detection algorithms

– Vector network analyzer (VNA) testing for impedance verification

– Cross-section analysis for multilayer registration validation

Quality assurance for Rogers PCBs goes beyond standard IPC requirements, incorporating:

– Time-domain reflectometry (TDR) for impedance profile analysis

– X-ray inspection for blind/buried via integrity

– Thermal cycling testing per MIL-STD-202 standards

– RF performance validation using network analyzers

For designers pushing the boundaries of high-frequency electronics, our Rogers PCB solutions offer:

1. Unmatched signal integrity up to 77GHz and beyond

2. Near-zero passive intermodulation (PIM) for sensitive receiver systems

3. Coefficient of thermal expansion (CTE) matched to copper for reliable plated through holes

4. Custom material combinations (hybrid constructions with FR-4) for cost-optimized designs

Reviews

There are no reviews yet.