Key Performance Advantages

Thermal Performance: High Tg variants (170-180°C) maintain stability during lead-free reflow processes

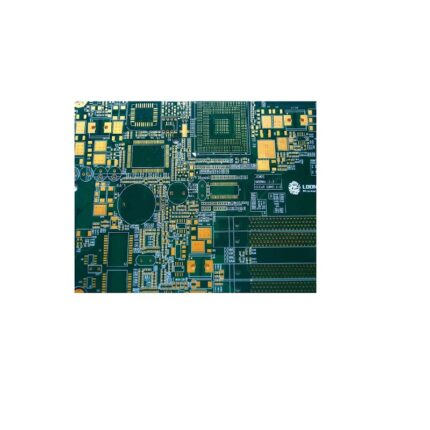

Signal Integrity: Controlled impedance capabilities (±10%) with tight dielectric thickness control

Mechanical Strength: Excellent peel strength exceeding 1.0N/mm

Environmental Resistance: UL94 V-0 flammability rating and superior CAF resistance

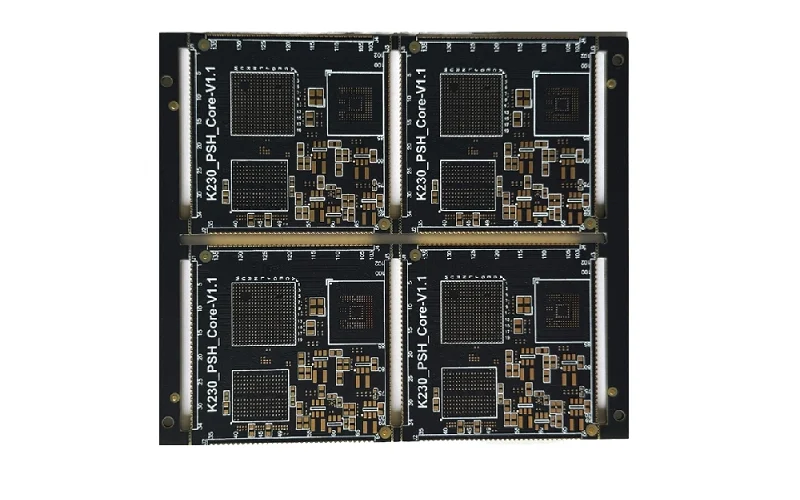

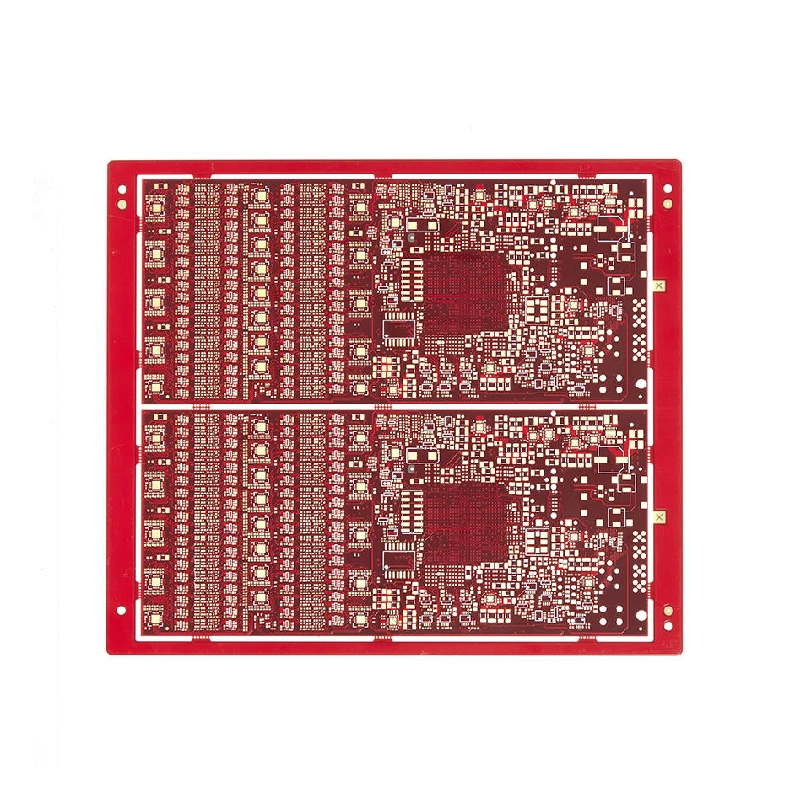

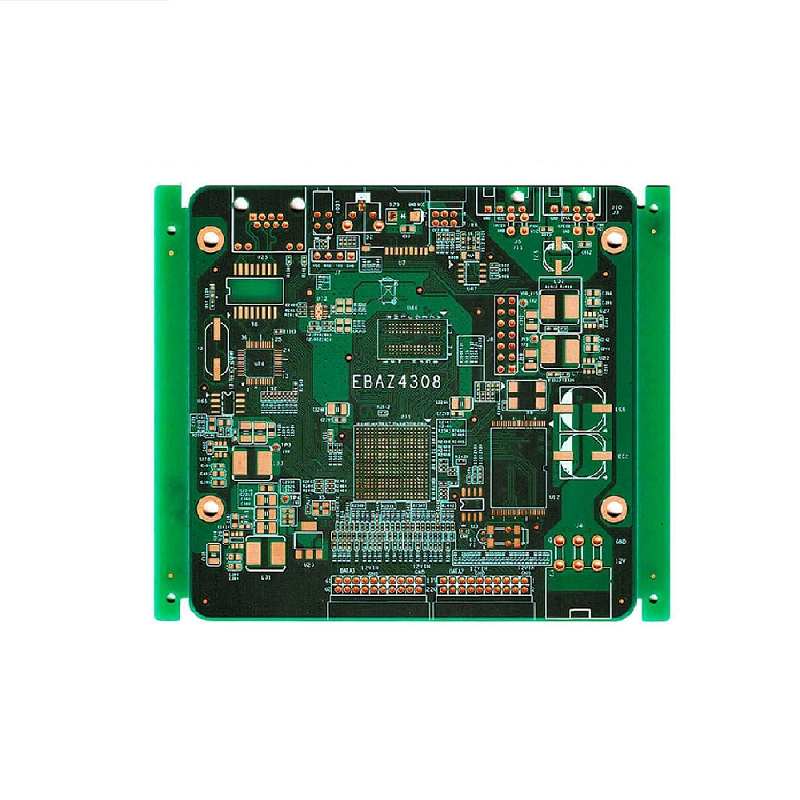

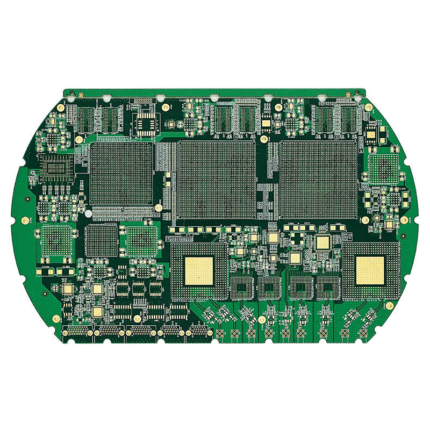

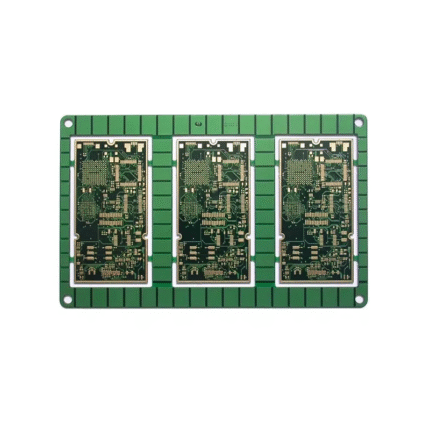

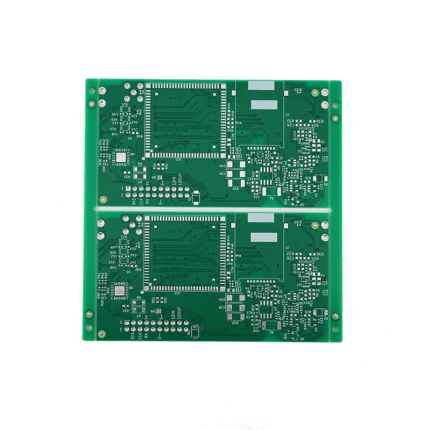

Advanced Manufacturing Capabilities

Our state-of-the-art production facilities employ cutting-edge technologies including:

Laser direct imaging for 25μm line/space resolution

Plasma desmear for optimal hole wall preparation

Automated optical inspection with 10μm defect detection

TDR methodology for impedance control verification

Quality Assurance

Every FR-4 PCB undergoes rigorous testing to ensure reliability:

100% electrical testing including Hi-Pot verification

Microsection analysis for plating quality assessment

Thermal stress testing per IPC-TM-650 standards

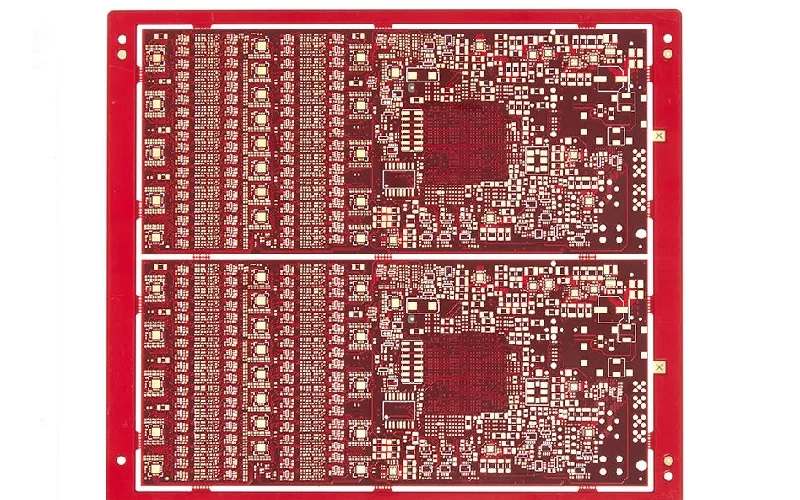

Specialized FR-4 Formulations

For enhanced performance requirements, we offer modified FR-4 materials featuring:

Low Dk (3.8-4.2) formulations for high-speed digital applications

Halogen-free compositions meeting environmental regulations

High CTI versions for operation in harsh conditions

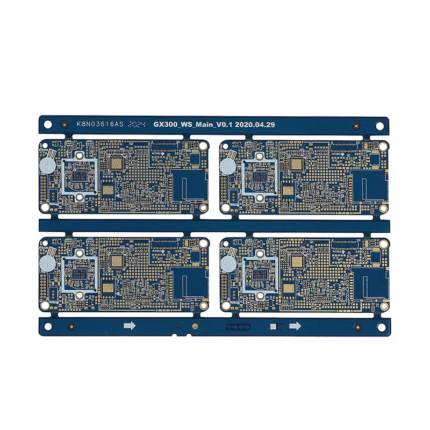

The continued preference for FR-4 PCBs across industries stems from their unmatched combination of performance, reliability and cost-effectiveness. As material science and manufacturing technologies advance, FR-4 remains the substrate of choice for everything from prototype development to high-volume production, delivering consistent quality and dependable performance in even the most demanding electronic applications.

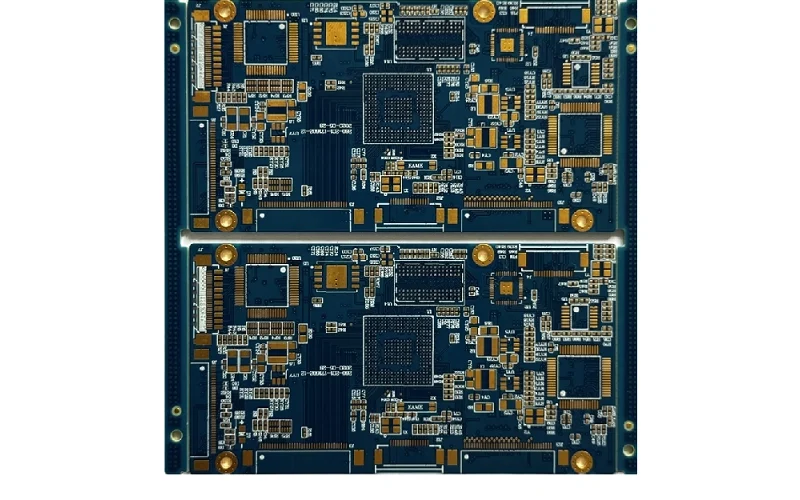

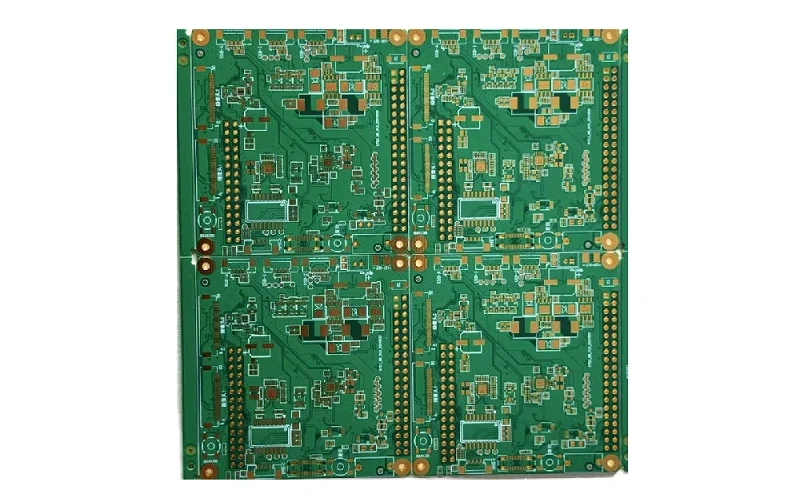

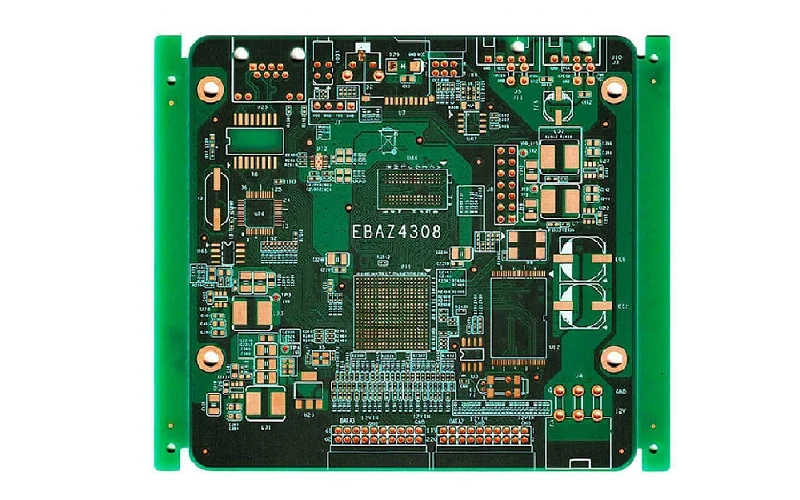

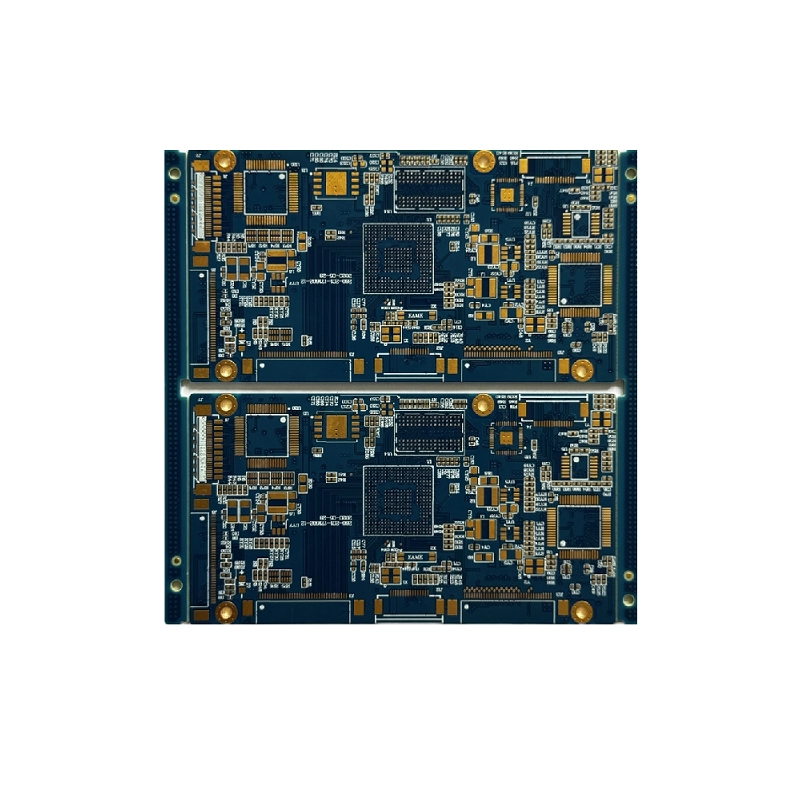

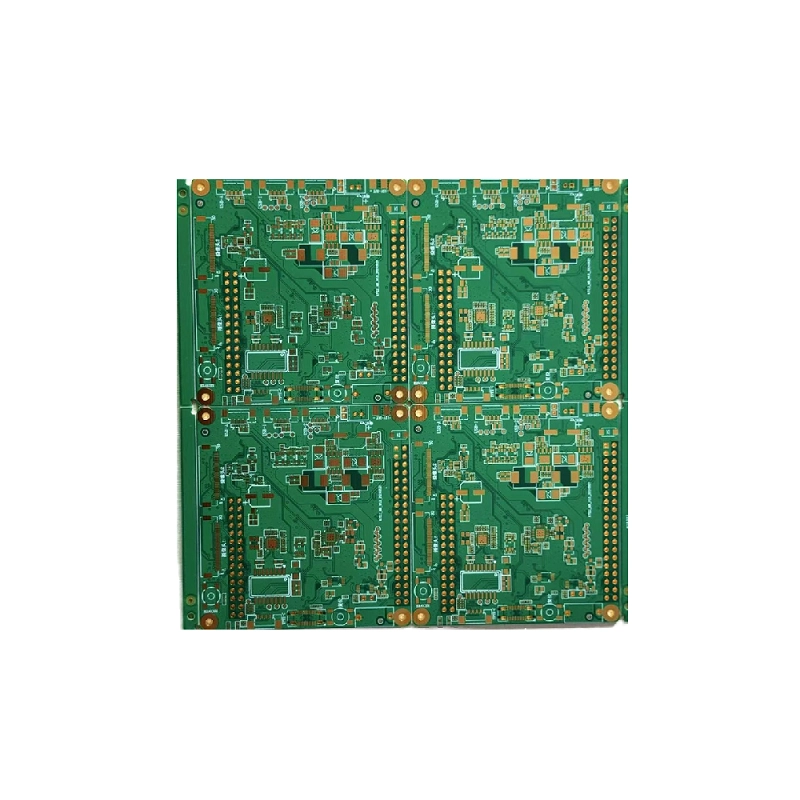

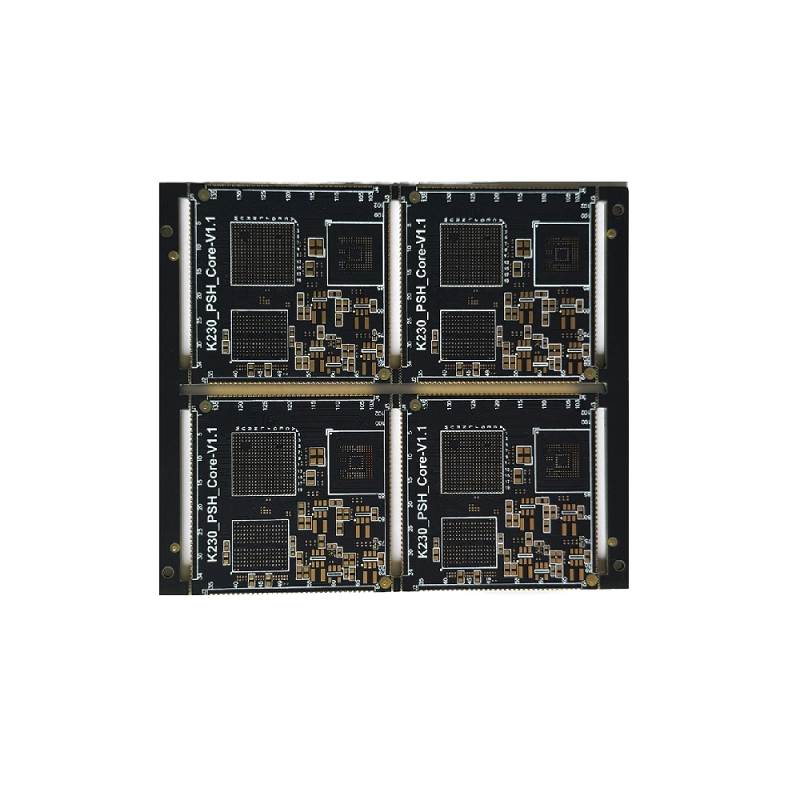

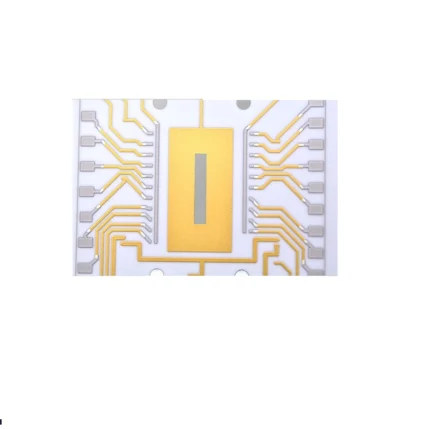

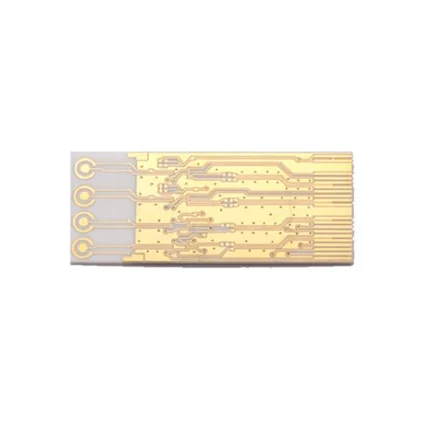

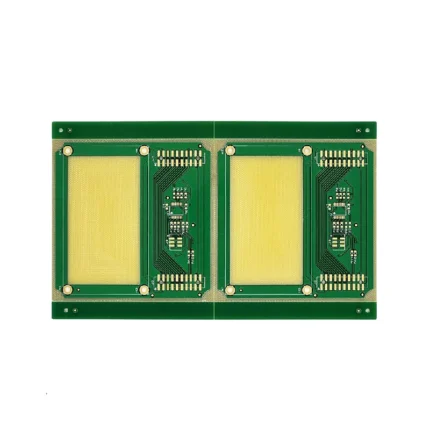

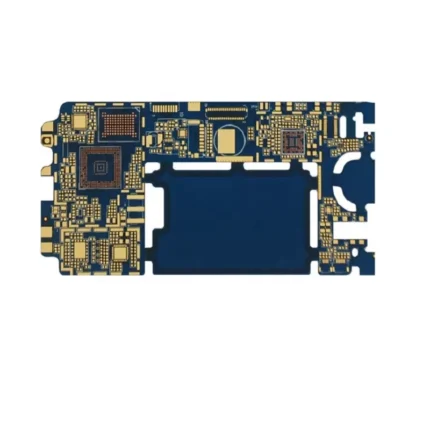

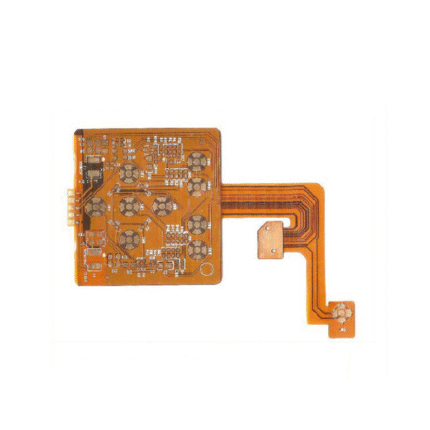

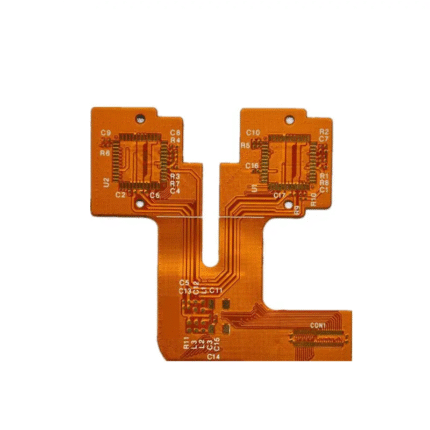

As the most widely used PCB substrate in the electronics industry, FR-4 glass-reinforced epoxy laminates provide the perfect combination of electrical performance, mechanical durability, and thermal stability. These high-performance circuit boards serve as critical components in applications ranging from consumer electronics and telecommunications equipment to automotive systems and aerospace technology.

With a dielectric constant between 4.3-4.8 at 1MHz and dissipation factors below 0.02, FR-4 PCBs maintain excellent signal integrity even in demanding high-frequency applications. The material’s superior insulation resistance (exceeding 10⁸ megohms) and high breakdown voltage make it ideal for circuits requiring reliable isolation between conductive layers.

Reviews

There are no reviews yet.