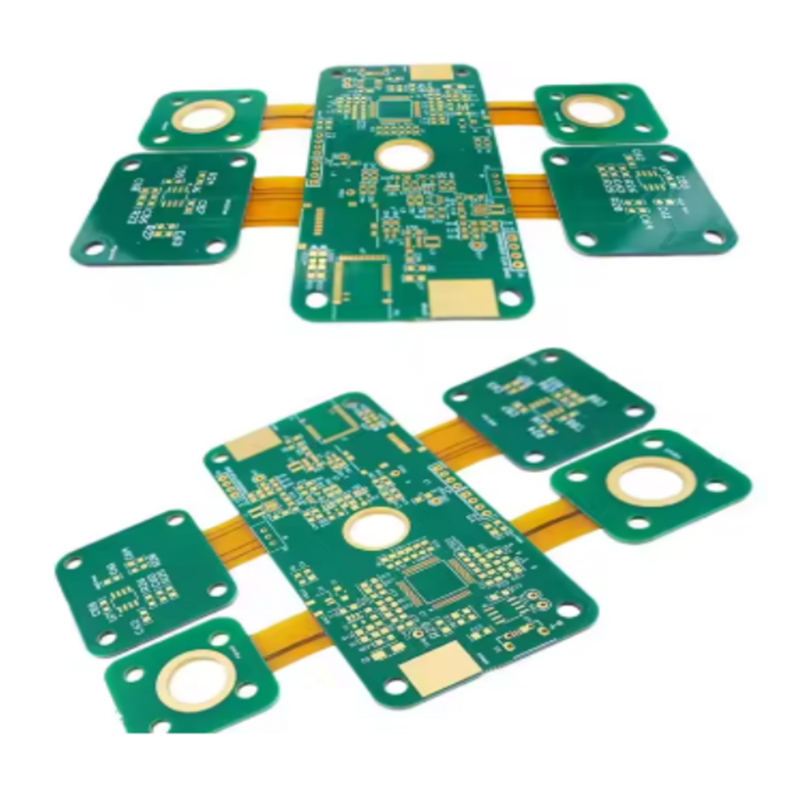

Mastering Complex Layer Transitions

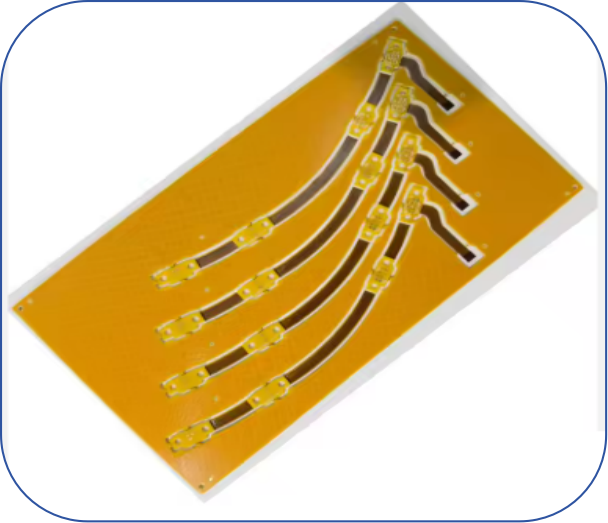

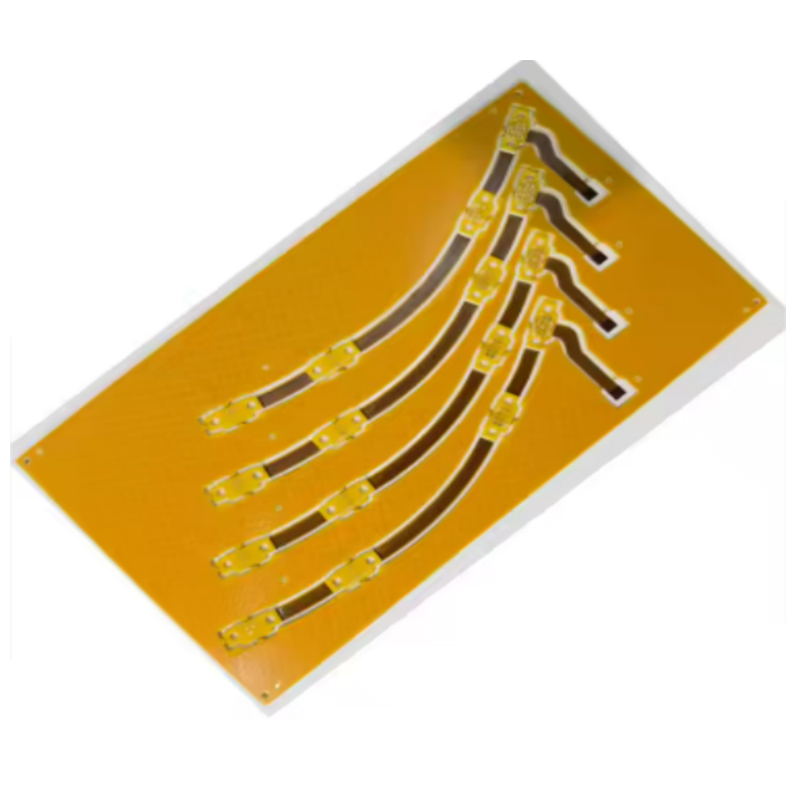

- Dynamic Flex Reliability – 200k+ bend cycle proven designs (IPC-6013D Class 3)

- Z-Axis Stability – <0.1% via cracking in transition zone

- Micro-Flex Precision – 50μm line/spacing on polyimide substrates

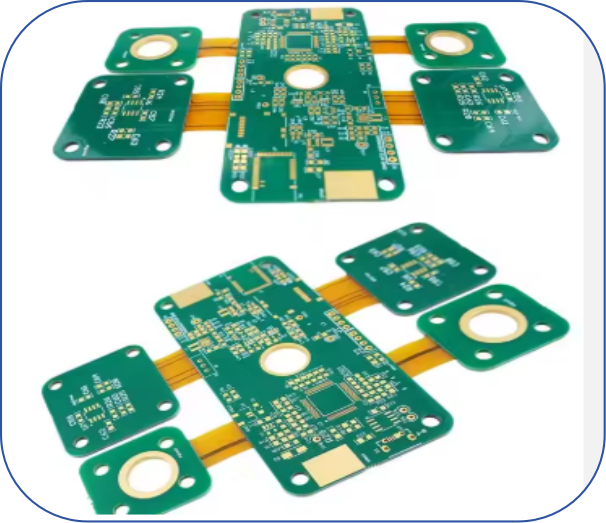

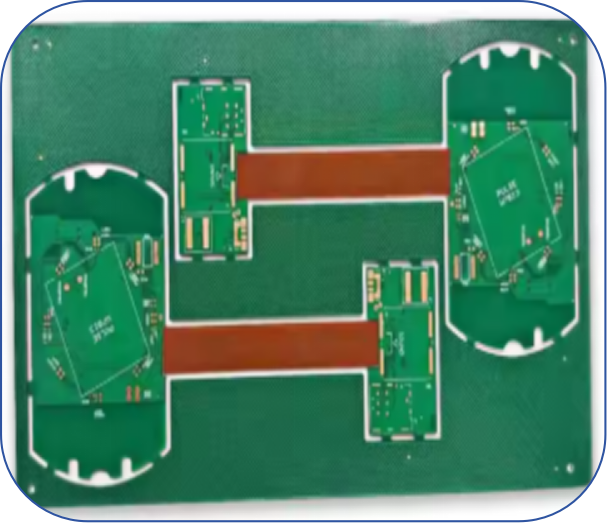

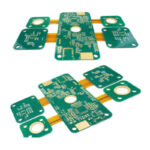

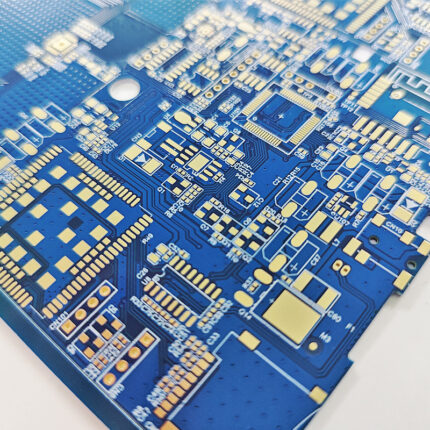

Core Rigid-Flex Assembly Capabilities

| Parameter | Capability | Technology/Equipment |

| Layer Configuration | 2-24L (Up to 8 flex layers) | Sequential lamination + laser ablation |

| Flex Material | Polyimide, PET, LCP | Autoclave-controlled curing |

| Bending Radius | 3X layer thickness (Static) / 6X (Dynamic) | 3D FEM simulation (Ansys) |

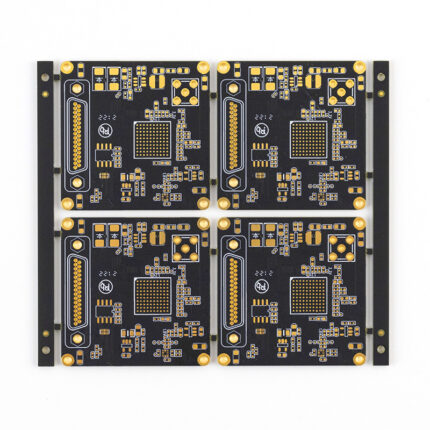

| Component Density | 01005 on rigid / 0201 on flex zones | Modified stencil designs + vacuum fixtures |

| Coverlay Precision | ±25μm registration | Laser-cut adhesiveless coverlays |

| Stiffener Integration | Aluminum/FR4/PI, 0.1-2.0mm | Thermally conductive bonding films |

| Fine-Pitch Assembly | 0.3mm pitch BGAs on rigid-flex joints | X-Ray aligned placement (Nordson DAGE) |

Rigid-Flex Assembly Process Flow

Critical Quality Controls

Material Science

CTE mismatch analysis (±1.5ppm/°C tolerance)

Adhesive peel strength >1.2N/mm (IPC-TM-650)

Process Validation

Flex Durability: 10k cycles

Thermal Shock: -55°C ↔ +125°C (100 cycles, MIL-STD-883)

Impedance Control: ±8% on 100Ω differential pairs

Defect Detection

Micro-section analysis of transition zones

TDR (Time Domain Reflectometry) for impedance verification

Acoustic microscopy for delamination screening

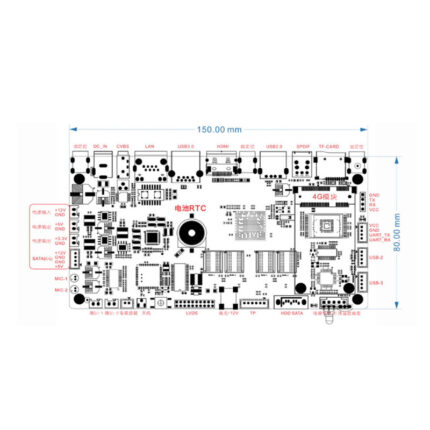

| PCB attributes | Flex | Rigid-flex | |

| Min Layer Count | 1 | 1 | |

| Max Layer Count | 12 | ≤ 32 | |

| Min Core thickness | .001″ (.025 mm) | 3 oz (89 ml) | |

| Max Finished Copper Weight (I/L) | 2 oz (59 ml) | 3 oz (89 ml) | |

| Max Finished Copper thickness (O/L) | 12 micron (.012 mm) | 9 micron (.009 mm) (only for O/L) | |

| Max Panel Size | 12×18 | 12×18 | |

| Smallest Mechanical Drill Diameter | .0079″ (.201 mm) | .0071″ (.180 mm) | |

| Smallest Laser Drill Diameter | No | .005″ (.127 mm) | |

| Min Finished Hole Size | .006″ (.152 mm) | .006″ (.152 mm) | |

| Max through Hole Aspect Ratio | 10:01 | 10:01 | |

| Max Blind Via Aspect Ratio | .75:1 | .75:1 | |

| Min Trace and Space | ≥ .0035”(.089 mm) | ≥ .0035”(.089 mm)(rigid) | |

| Min Pad Size for Test | .016″ (.406 mm) | .005” (.127 mm) (rigid) | |

| Process Pad Diameter | D + .014″ (.356 mm) (1-mil (.025 mm) annular ring) | D + .014″ (.356 mm) (1-mil (.025 mm) annular ring) | |

| Stacked Vias | No | No | |

| Min Wire Bond Pad Size | > .006″ (.152 mm) | > .006″ (.152 mm) | |

| Controlled Impedance Tolerance | 10% | 5% | |

| Solder Mask Registration | Within .002″ (.051 mm) | Within .002″ (.051 mm) | |

| Solder Mask Feature Tolerance | .001″ (.025 mm) | .001″ (.025 mm) | |

| Solder Mask Min Dam Size | .004″ (.102 mm) | .001″ (.025 mm) | |

| Min Diameter Route Cutter Available | .019″ (.483 mm) | .024″ (.610 mm) | |

| Mechanical Routed Part Size Tolerance | .003″ (.076 mm) | .010″ (.254 mm) | |

| Bow and Twist Tolerance | N/A | As per spec | |

| Thickness Tolerance | +/- .002″ (.051 mm) | 10% | |

| Sequential Laminations | N/A | 2 | |

| Buried Vias | Yes | Yes | |

| Blind Vias | Yes | Yes | |

| Conductive Filled Vias | No | Yes | |

| Non Conductive Filled Vias | No | Yes | |

Advanced Engineering Support

DFM Pro Toolkit

Bend radius calculator with strain analysis

Stiffener placement optimization algorithms

Flex-to-rigid transition zone spacing rules

Prototyping Accelerators

72-hour quick-turn rigid-flex samples

3D printed folding jigs for form validation

Failure Prevention

38-point rigid-flex specific checklist

HAST testing (130°C/85%RH, 96hrs)

Certified Rigid-Flex Ecosystem

ISO 13485 IATF16949

Standards: IPC-6013D Class 3

Reviews

There are no reviews yet.