From Traceability to Launch: Total Control in Aerospace PCB Production

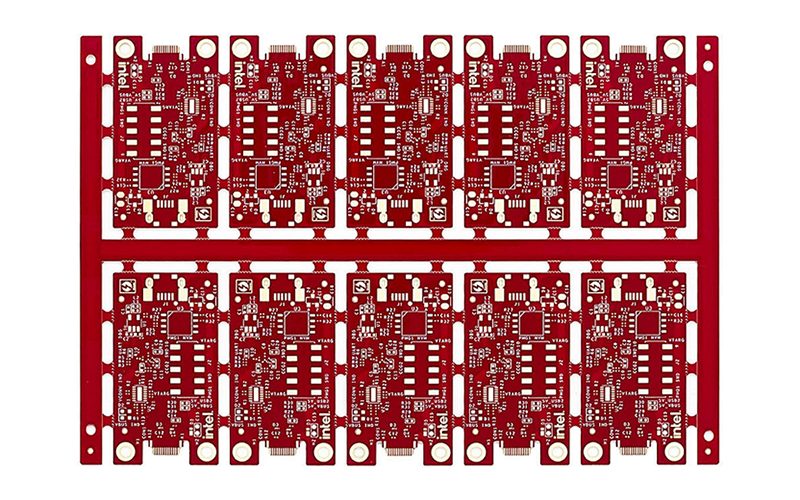

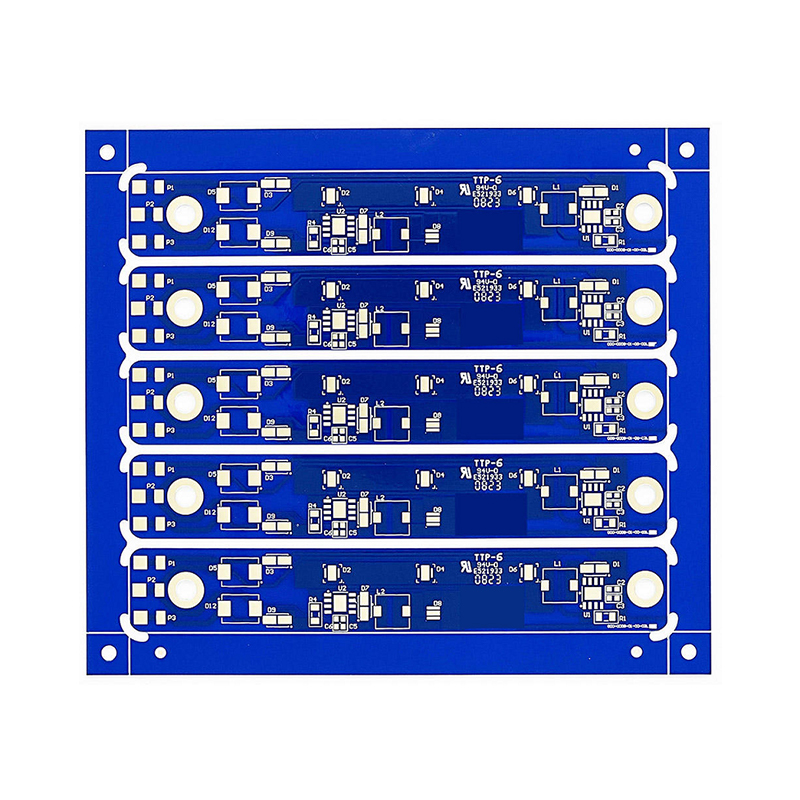

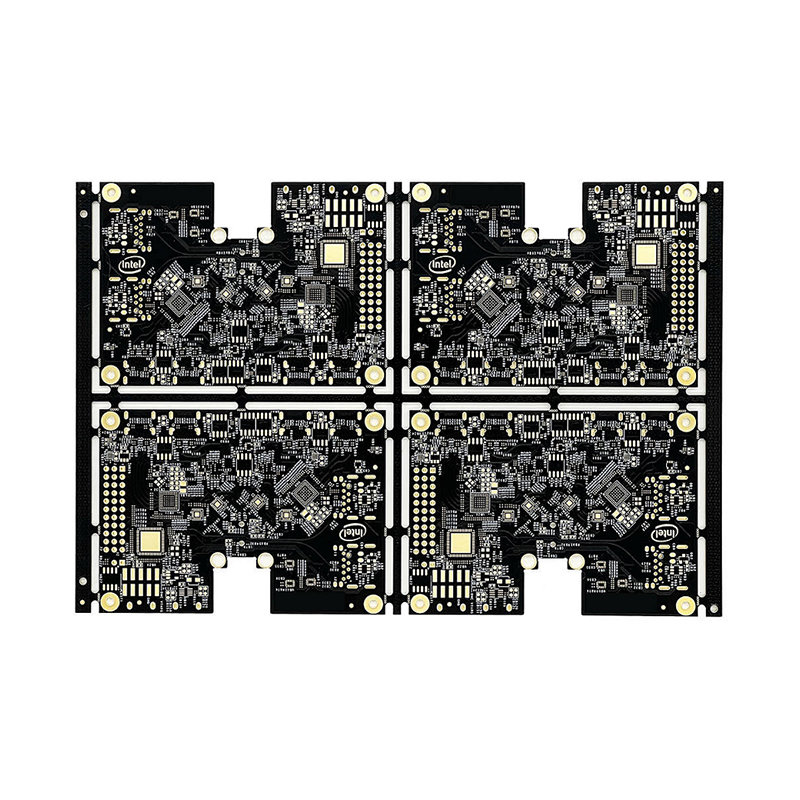

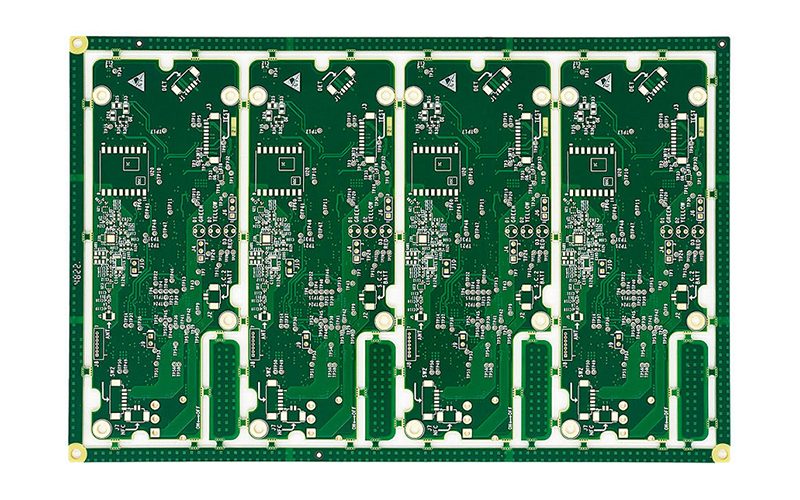

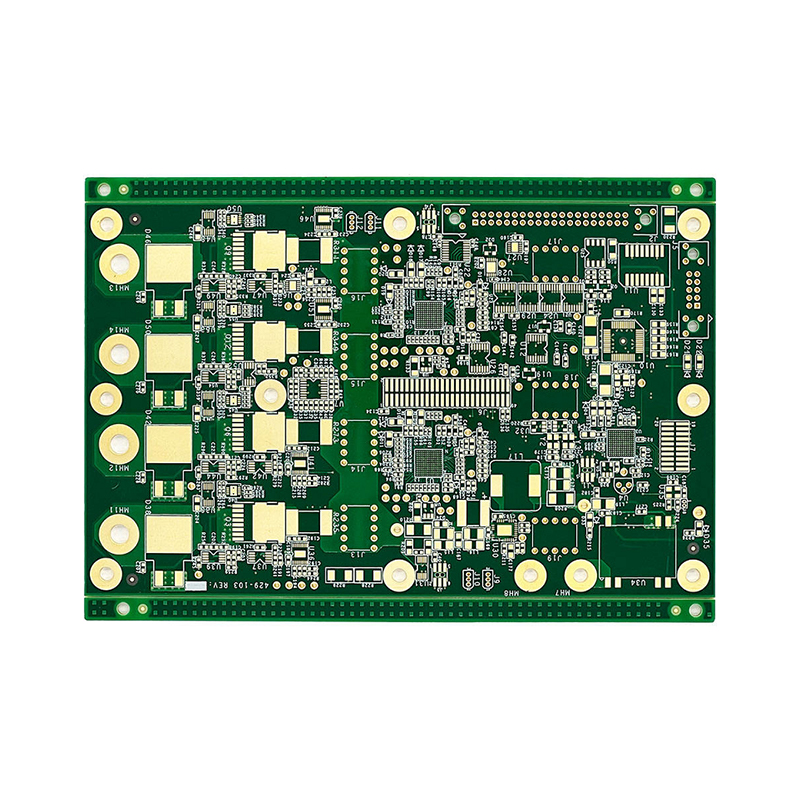

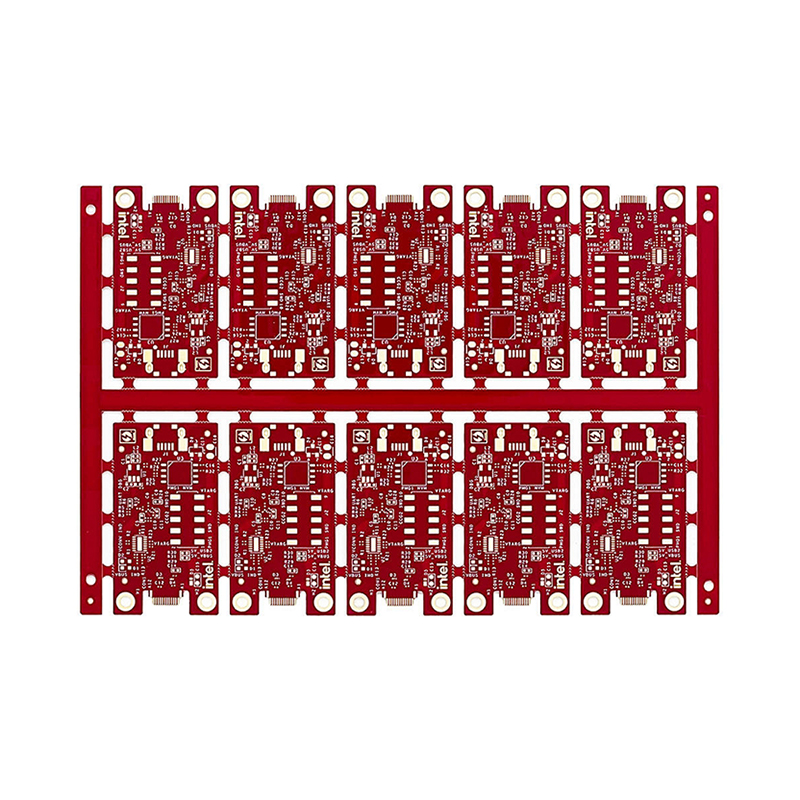

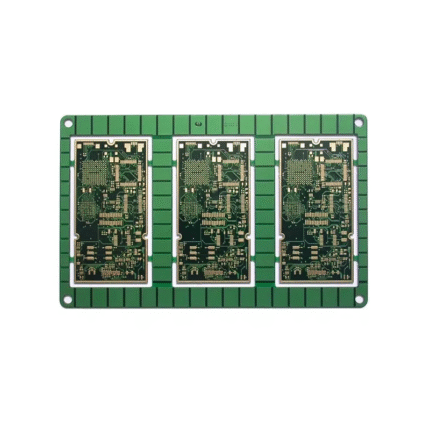

Our aerospace PCBs are manufactured with exhaustive process controls and documentation, including full material traceability, process certification, and lot-specific testing data. Every board undergoes rigorous qualification testing before being approved for mission use, with optional hermetic sealing and radiation hardening available for space applications.

Reliability at Altitude: PCBs for Aviation, Space & Defense

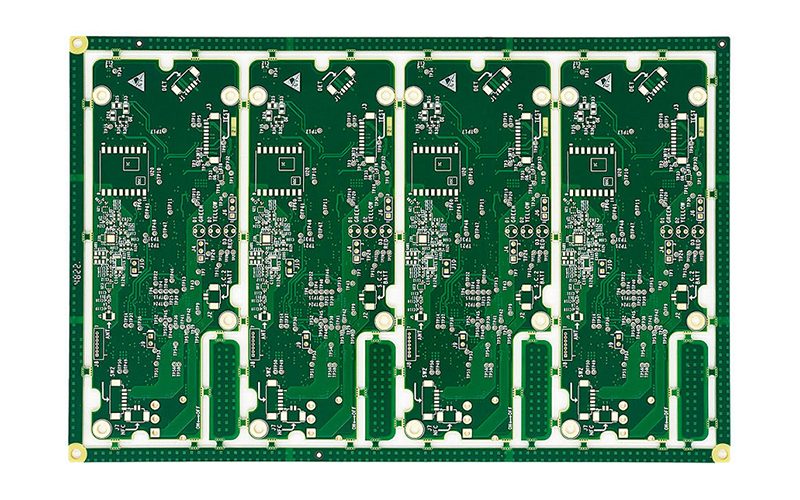

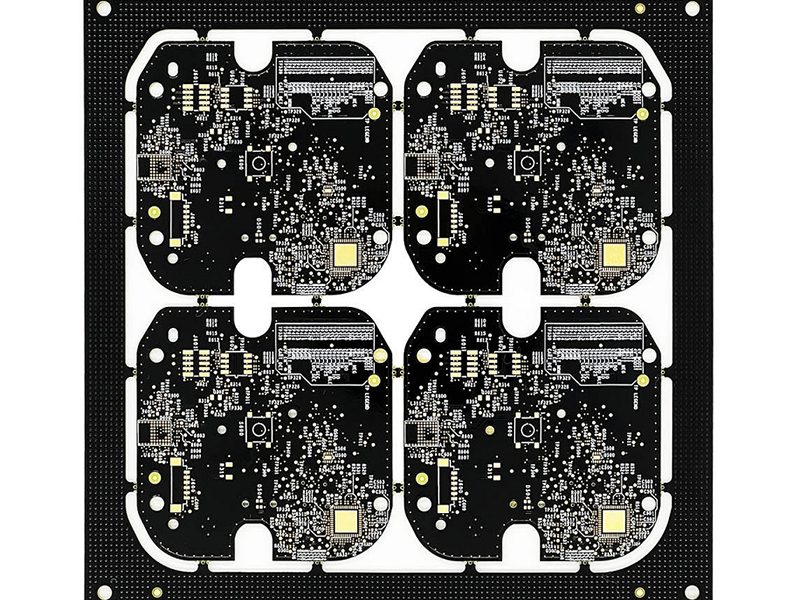

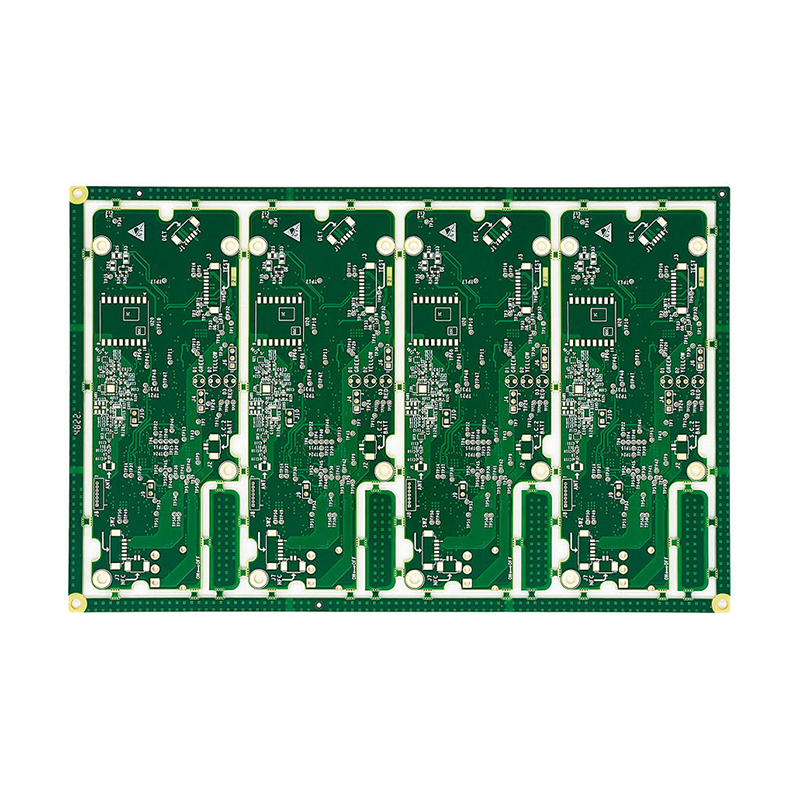

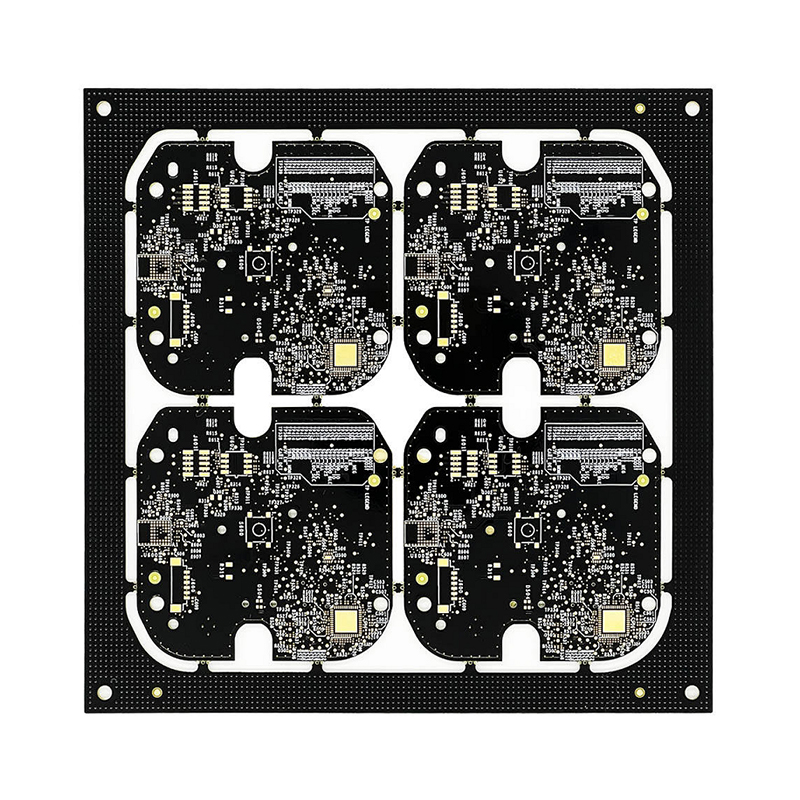

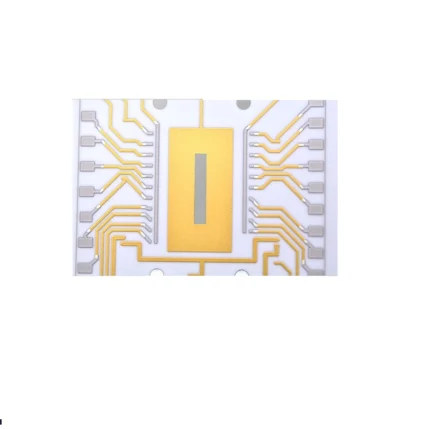

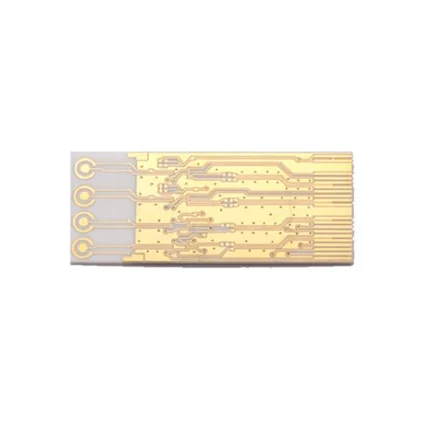

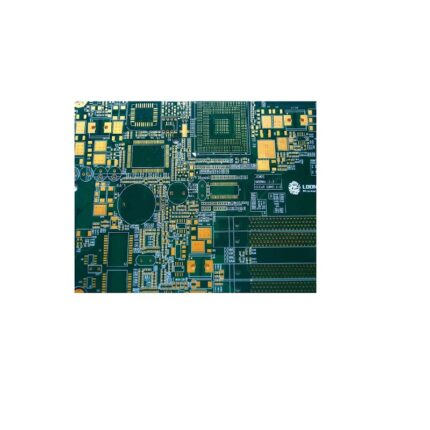

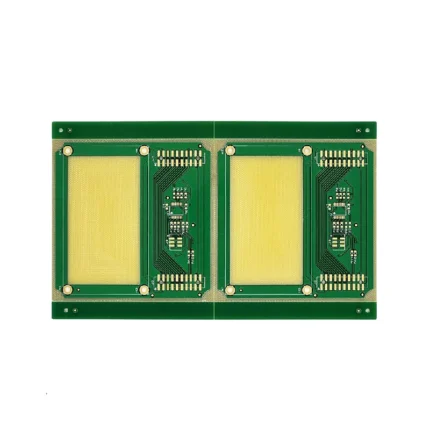

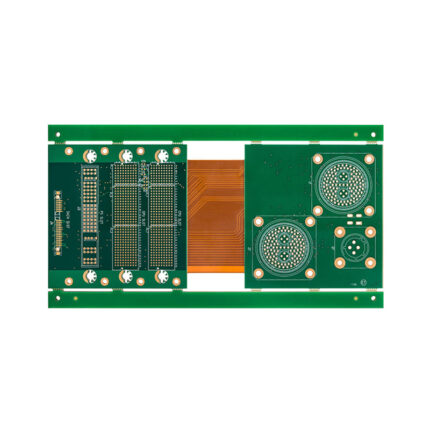

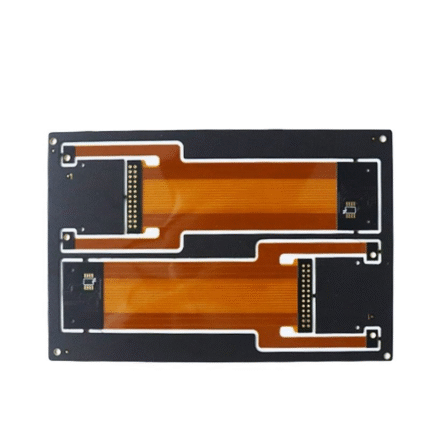

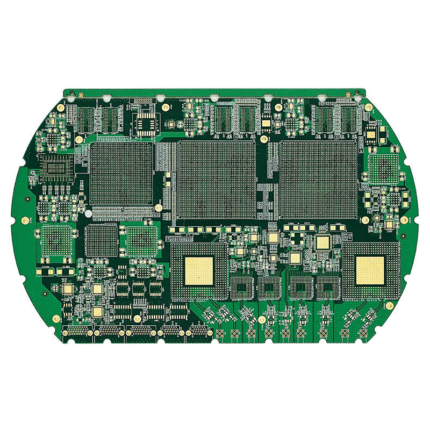

Aerospace PCBs are engineered to meet the most demanding requirements of aviation, space exploration, and defense systems where reliability under extreme conditions is non-negotiable. These specialized printed circuit boards must withstand intense vibration, dramatic temperature fluctuations, cosmic radiation, and prolonged operational lifecycles while maintaining flawless electrical performance. Designed for applications ranging from satellite communications to flight control systems, aerospace PCBs incorporate advanced materials and rigorous manufacturing processes that far exceed commercial-grade standards.

Thermal Stability from -65°C to +260°C—Ready for Any Altitude

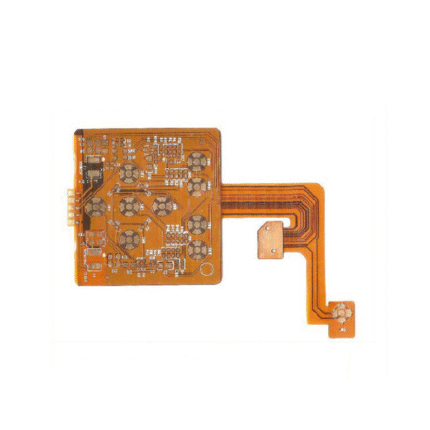

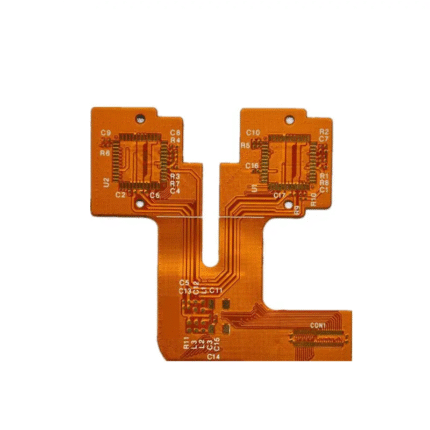

The exceptional durability of aerospace PCBs comes from carefully selected materials and construction methods. High-performance substrates like polyimide, ceramic-filled PTFE, and high-Tg FR-4 provide the foundation, offering thermal stability from -65°C to +260°C and dielectric constants tailored for RF and high-speed digital applications. These materials are combined with military-grade copper cladding and specialized conformal coatings to create circuit boards capable of surviving the harshest environments encountered in stratospheric flight and orbital operations.

Satellite Systems

Payload Electronics

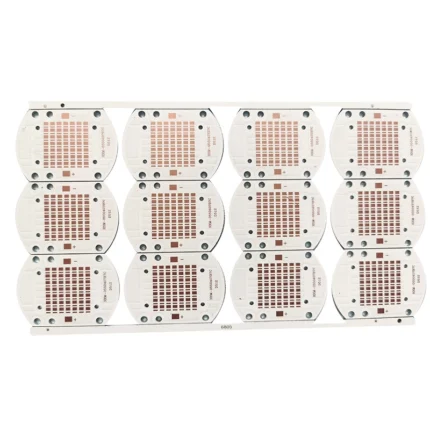

These circuit boards manage and process the core mission data, including imaging, communication signals, and environmental sensing. Built to withstand radiation, vacuum, and temperature extremes, they ensure consistent operation in orbit.Power Distribution Units (PDUs)

Aerospace-grade PCBs efficiently regulate and distribute electrical power across all onboard systems. Their design emphasizes thermal management, voltage stability, and redundancy to prevent mission failure.Attitude Control Systems (ACS)

PCBs used in ACS modules control the satellite’s orientation and positioning. These boards must process sensor data and drive actuators with high precision, often in real-time, requiring low-latency and high-reliability signal pathways.

Aircraft Avionics

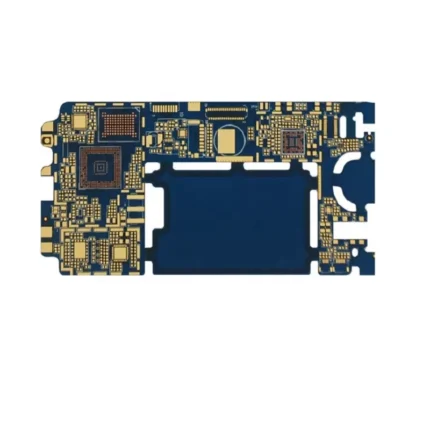

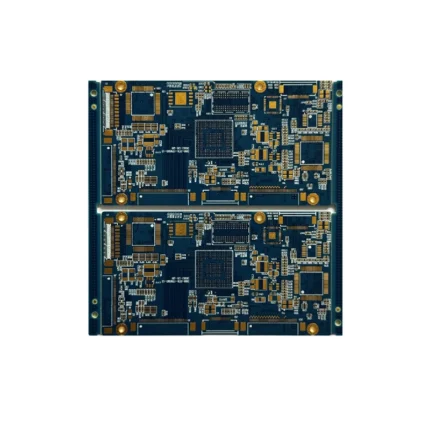

Flight Control Computers

These systems rely on rugged, high-density PCBs to process real-time flight data, execute pilot commands, and interface with sensors and actuators. Reliability and low-latency response are critical for ensuring safe and stable flight performance.Engine Monitoring Systems

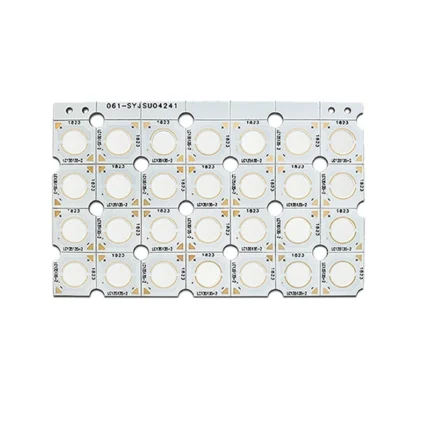

PCBs in engine control units (ECUs) gather, process, and transmit vital data such as temperature, pressure, and RPM. Designed to endure high thermal loads and vibration, these boards enable predictive maintenance and engine efficiency.Cockpit Displays

Avionics displays depend on compact, multi-layer PCBs to power high-resolution screens, manage flight data visualization, and integrate with navigation and communication systems. These boards must be both EMI-resistant and lightweight.

Defense Electronics

Radar Signal Processing

Radar systems require high-speed, low-noise PCBs capable of processing vast amounts of data in real time. These boards must ensure signal integrity, EMI shielding, and temperature stability under constant operational stress.Electronic Warfare Systems

PCBs in EW platforms handle advanced threat detection, jamming, and countermeasure coordination. They are engineered with high-density interconnects, RF optimization, and multi-layer shielding to guarantee responsiveness and signal clarity.Missile Guidance Systems

Guidance electronics demand compact, ultra-reliable boards that can operate under high G-forces and rapid thermal changes. These PCBs integrate inertial sensors, GPS modules, and control logic in a tightly confined space.

Unmanned Systems

Drone Flight Controllers

These PCBs serve as the brain of unmanned aerial vehicles (UAVs), processing input from sensors, GPS, and user commands to maintain stable flight. Boards must be lightweight, vibration-resistant, and capable of real-time data processing.Surveillance Equipment

Circuit boards in surveillance drones and robotic systems support HD video capture, secure wireless transmission, and signal encryption. Their design requires thermal efficiency, EMI shielding, and reliable power regulation in mobile environments.Autonomous Navigation

Used in land and air vehicles, these PCBs integrate AI processors, lidar, GPS, and sensor fusion modules. They must handle high data bandwidth and computational loads while ensuring long-term reliability under motion and environmental stress.

Reviews

There are no reviews yet.