The choice between traditional PCB assembly and Rigid-Flex PCB Assembly can significantly impact the performance, reliability, and cost-effectiveness of your project. As electronics continue to shrink in size while growing in functionality, understanding the advantages and limitations of each assembly type is crucial. This article explores the key differences, applications, and considerations to help you determine which solution fits your project best.

Understanding Traditional PCB Assembly

Traditional PCB assembly typically involves either single-layer or multi-layer rigid boards. These boards are characterized by their flat, solid structure and are widely used across industries.

Key Features of Traditional PCB Assembly

-

Rigid structure: Provides a stable platform for component placement.

-

Cost-effective for standard applications: Ideal for mass production of simpler electronics.

-

Wide availability: Numerous manufacturers and suppliers offer traditional PCB assembly services.

While traditional PCB assembly works well for many applications, it has limitations when space constraints, flexibility, and weight reduction are critical. For projects requiring compact designs, dynamic bending, or 3D integration, traditional PCBs may not be sufficient.

What is Rigid-Flex PCB Assembly?

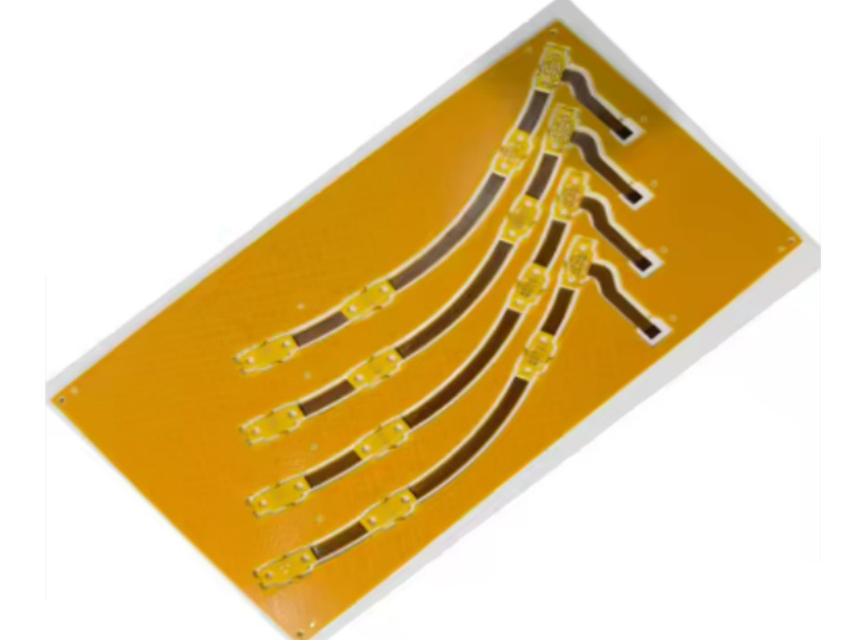

Rigid-Flex PCB Assembly combines the stability of rigid boards with the flexibility of flex circuits, creating a versatile solution that can bend or fold while maintaining electrical integrity. This hybrid design is ideal for advanced electronics where space optimization and mechanical flexibility are essential.

Advantages of Rigid-Flex PCB Assembly

-

Space-saving design: Enables compact layouts by folding or bending flexible sections.

-

Durability: Reduces solder joint stress due to fewer connectors and interconnections.

-

Weight reduction: Particularly beneficial in aerospace, medical devices, and wearable electronics.

-

High reliability: Flexible sections absorb mechanical stress, reducing the risk of circuit damage.

Manufacturers offering rigid-flex PCB assembly solutions are able to produce designs that integrate multiple rigid and flexible layers seamlessly, resulting in more robust and lightweight electronic assemblies.

Key Differences Between Rigid-Flex and Traditional PCB Assembly

| Feature | Traditional PCB Assembly | Rigid-Flex PCB Assembly |

|---|---|---|

| Structure | Fully rigid board | Combination of rigid and flexible layers |

| Flexibility | None | High, can bend/fold |

| Space Efficiency | Moderate | Excellent for compact designs |

| Weight | Standard | Reduced due to flexible layers |

| Durability | Good for static applications | High, stress-resistant in dynamic applications |

| Cost | Lower for simple designs | Higher due to complexity |

| Applications | Consumer electronics, industrial boards | Aerospace, medical devices, wearable electronics, complex systems |

This table highlights why choosing the right assembly type is critical for project success. While traditional PCBs are cost-effective and suitable for many applications, Rigid-Flex PCB Assembly provides unique advantages in modern electronics requiring compact, lightweight, and mechanically flexible solutions.

Applications of Rigid-Flex PCB Assembly

Rigid-Flex PCB Assembly solutions are particularly valuable in industries where performance, reliability, and space efficiency are priorities. Some common applications include:

-

Medical Devices: Compact and reliable circuits for devices like portable monitors, imaging systems, and diagnostic equipment.

-

Aerospace and Defense: Lightweight and stress-resistant PCBs for satellites, avionics, and military electronics.

-

Wearable Electronics: Flexible circuits for smartwatches, fitness trackers, and health monitoring devices.

-

Industrial Equipment: High-density assemblies for robotic systems and precision instrumentation.

Choosing a reputable rigid-flex PCB manufacturer or rigid-flex PCB supplier ensures that your assemblies meet strict quality, safety, and performance standards, especially for critical applications.

How to Choose the Right Rigid-Flex PCB Supplier

Selecting a reliable rigid-flex PCB manufacturer is essential to achieving high-quality results. Consider the following factors:

-

Experience and Expertise: Look for suppliers with proven experience in producing complex rigid-flex assemblies.

-

Customization Capabilities: Your project may require tailored solutions, including layer counts, flex routing, and material selection.

-

Certifications: ISO, UL, and IPC certifications demonstrate compliance with industry standards.

-

Prototyping and Testing: Reputable suppliers offer prototyping services and rigorous testing to ensure reliability.

-

Technical Support: Strong technical collaboration helps address design challenges and optimize performance.

Working with a professional rigid-flex PCB supplier can simplify the design and manufacturing process while reducing the risk of costly mistakes.

Cost Considerations

While Rigid-Flex PCB Assembly solutions are more expensive than traditional PCBs due to complexity and material requirements, the total cost of ownership can be lower in many cases. Benefits such as reduced connector usage, lower assembly weight, and improved durability can offset higher initial costs, especially in high-performance or space-constrained applications.

Conclusion:

Choosing between traditional PCB assembly and Rigid-Flex PCB Assembly depends on your project’s specific requirements. Traditional PCBs remain suitable for standard applications with minimal space constraints and lower complexity. However, for modern electronics requiring compact designs, flexibility, and high reliability, rigid-flex PCB assembly solutions offer significant advantages.

Partnering with an experienced rigid-flex PCB manufacturer or rigid-flex PCB supplier ensures that your assemblies meet performance expectations while optimizing space, weight, and durability. By understanding the differences and applications of each assembly type, you can make informed decisions that enhance your project’s success and efficiency.