As electronic devices continue to evolve, the demand for high-density and high-performance printed circuit boards (PCBs) has increased significantly. BGA assembly plays a critical role in meeting these requirements, providing a reliable solution for connecting integrated circuits with PCBs in compact designs. Companies like Baiyoudi have established themselves as leaders in bga assembly service, offering advanced capabilities to support modern electronics manufacturing.

Understanding BGA Assembly

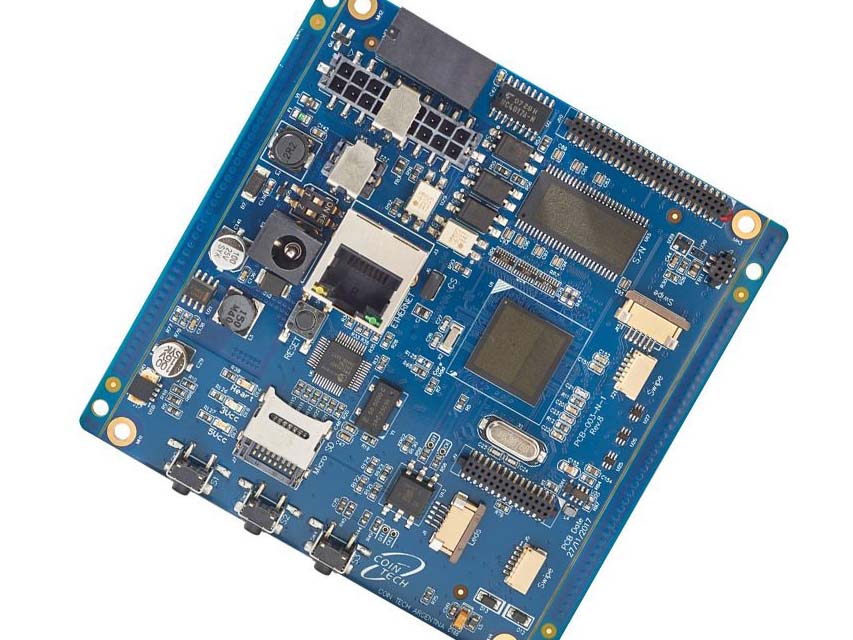

Ball Grid Array (BGA) is a type of surface-mount packaging used for integrated circuits. Unlike traditional leaded components, BGA packages feature an array of solder balls on the underside of the chip, providing multiple electrical connections to the PCB. This design allows for higher pin density, improved thermal performance, and better signal integrity, making it ideal for modern electronic applications such as smartphones, networking equipment, and computing devices.

BGA assembly capabilities include precise soldering, component placement, and inspection processes to ensure every connection meets quality standards.

Key BGA Assembly Capabilities

1. High-Precision Component Placement

The accuracy of component placement is a critical aspect of bga assembly service. Advanced pick-and-place machines can position BGA components with micron-level precision, reducing the risk of solder bridging or misalignment. This ensures reliable electrical connections, even for densely packed PCBs.

2. Soldering and Reflow Expertise

Proper soldering is essential for BGA assembly, as the solder balls must melt evenly and create strong connections without damaging the components. Leading bga assembly providers like Baiyoudi use advanced reflow ovens and controlled temperature profiles to guarantee consistent results. This capability supports a wide range of solder types, including lead-free and high-temperature solder, which are increasingly required in modern electronics.

3. Inspection and Testing

Inspection is a vital component of bga assembly capabilities. Techniques such as X-ray inspection, automated optical inspection (AOI), and functional testing help identify defects like solder voids, shorts, or open circuits. By integrating rigorous quality control, Baiyoudi’s bga assembly service ensures high reliability and long-term performance for end devices.

4. Multi-Layer PCB Support

Modern electronics often rely on multi-layer PCBs to accommodate complex circuits. Advanced bga assembly capabilities include the ability to handle dense boards with multiple layers, ensuring proper thermal management and signal integrity. This is essential for applications in high-speed computing, telecommunications, and aerospace industries.

5. Prototyping and Small-Batch Production

A versatile bga assembly service also supports rapid prototyping and small-batch production. This allows designers to test new products quickly and adjust layouts or materials before full-scale manufacturing. Companies like Baiyoudi provide flexible production options that balance speed, quality, and cost-efficiency.

6. Reliability and Compliance

Modern electronics must meet strict reliability and safety standards. Advanced bga assembly capabilities include process validation, traceability, and compliance with international standards such as IPC-A-610, RoHS, and ISO certifications. These measures ensure that every PCB assembled can withstand thermal cycles, mechanical stress, and long-term operation in demanding environments.

Why Choose Baiyoudi for BGA Assembly

Baiyoudi has become a trusted provider of bga assembly services thanks to its combination of advanced equipment, skilled technicians, and rigorous quality control. The company offers:

-

State-of-the-art pick-and-place and reflow equipment

-

High-precision inspection, including X-ray and AOI

-

Flexible prototyping and small-batch production capabilities

-

Compliance with international quality standards

By leveraging these bga assembly capabilities, Baiyoudi ensures that clients receive reliable, high-performance PCBs suitable for modern electronics applications.

Conclusion:

The success of modern electronics heavily depends on advanced bga assembly capabilities. Accurate placement, precise soldering, rigorous inspection, and compliance with industry standards are all critical for reliable PCB manufacturing. Companies like Baiyoudi provide professional bga assembly service, helping electronics manufacturers produce high-quality, high-performance devices that meet the demands of today’s market.